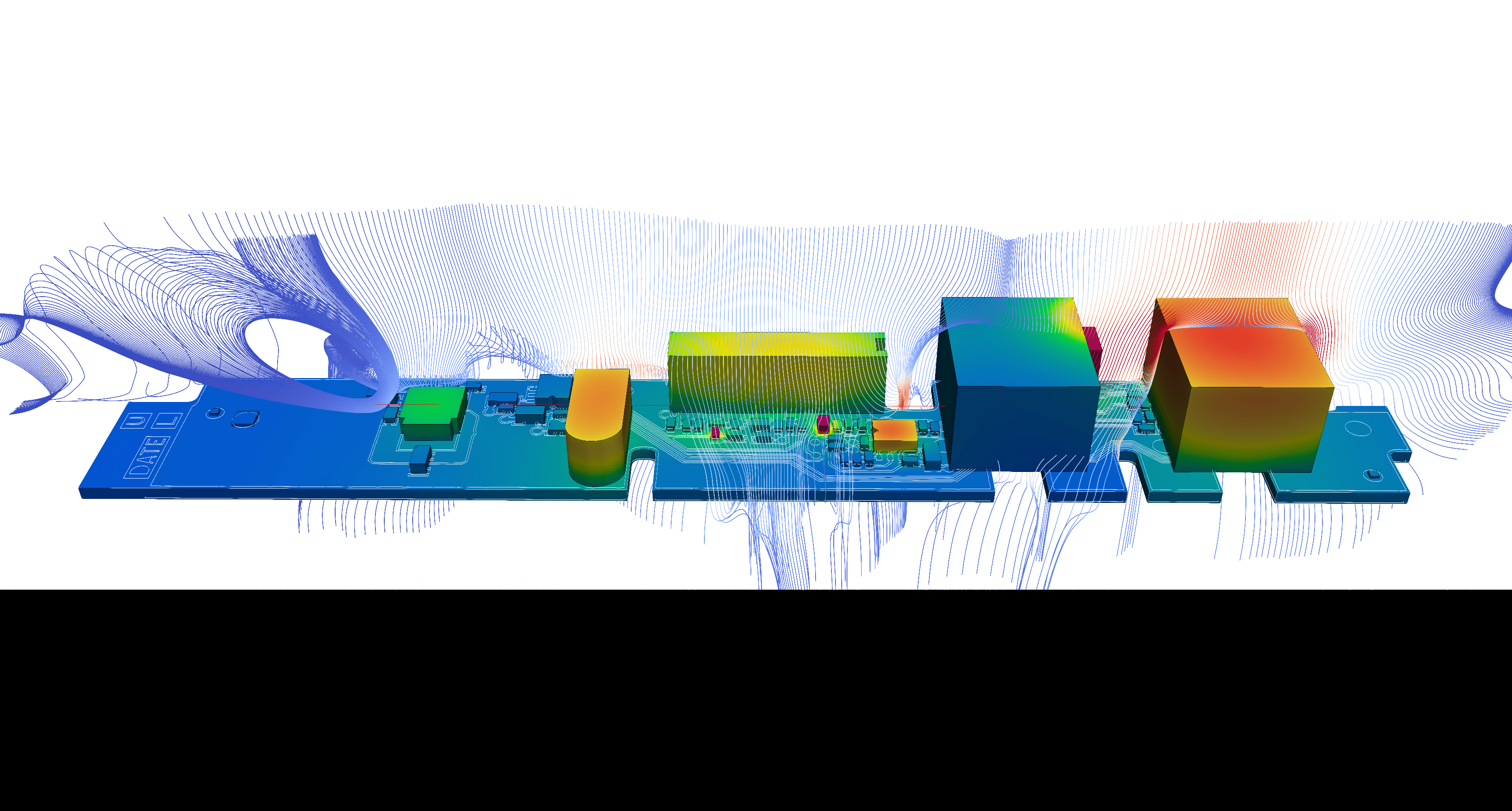

End-to-end electronic system design

Altair’s new electronic system design toolset enables engineers developing smart, connected devices to collaborate on all aspects of physical, logical, thermal, electrical, and mechanical design. This accelerates a variety of applications, from more efficient printed circuit board (PCB) design review, verification, analysis, and manufacture to the design of motors, sensors, and actuators with simulation. Notable updates include:

- Improved simulation and optimisation of wireless connectivity, including 5G and electromagnetic compatibility

- Visual firmware development now supports more widely used microcontroller families

- More capabilities for PCB fabrication, assembly, and end-of-line testing

- Expanded workflows simplify and automate analysis of structural stress, vibration, thermal, and drop-test performance for non-experts

Improved simulation of real-world product performance

Altair’s ability to solve the most complex problems has expanded while delivering improved performance on graphics processing unit (GPU) and central processing unit (CPU) hardware on desktops, private, public, and hybrid-cloud environments. This faster, more accurate simulation of real-world product performance is addressed through these updates:

- Expanded modeling and visualization user experience includes workflows that support the entire topology modeling and meshing process, cutting task time from hours to minutes. Modeling fidelity in complex models is improved with more sophisticated and realistic representations of connectors.

- Advanced physics models that require the co-simulation of fluids and discrete elements, such as simulating particles in an air flow are now possible.

- Aeroelastic effects of aircraft wings can be analyzed to solve for flutter and other potential design issues.

- Altair’s SimSolid™ game-changing simulation technology for designers, engineers, and analysts is ten times faster than its original release.

- All simulation products are supported by the new Altair Material Data Center, which includes the largest number of plastic materials and properties available on the market.

Expanded simulation-driven design for manufacturing (SDfM)

Altair pioneered SDfM, bringing manufacturing simulation into the earliest stages of concept design with fast, accurate solvers and intuitive interfaces. The expanding functionality of Altair’s SDfM offering now spans casting, stamping, molding, extrusion, additive, and foaming. Additionally, Altair simulation solutions are increasingly used in process manufacturing during research, development, and process improvement in industries that produce bulk quantities of goods, including pharmaceuticals, food, cosmetics, and chemicals.

- Inspire Mold™ is rapidly becoming the industry benchmark for injection molding simulation in the early stages of product design.

- Inspire PolyFoam™ simulates the molding of foam components and rigid foam panels with polyurethane foams used in a wide range of industrial and household applications.

These updates will help customers across a broad range of industries – from automotive and aerospace to energy, healthcare, and high tech – solve complex problems as they advance the development of their smart, connected products by leveraging 5G, electromagnetics, and the Internet of Things.

Leave a Reply