Advik Hi-Tech Pvt. Ltd. has augmented its product portfolio in line with its Bharat Stage VI and electrification strategy.

Story by: Deven Lad

Pune based Advik Hi-Tech Pvt. Ltd. has long been pursuing its Bharat Stage VI (BSVI) and electrification strategy. At the Auto Expo 2020, the company showcased a slew of BSVI and EV products as a testimony to the company has augmented its product portfolio. Among crucial developments hinting at the strategy paying off according to Maneesh Satarkar, Vice President-Marketing and Business, Advik Hi-Tech Pvt. Ltd. was the company winning order of three million units of a new BSVI engine complying with its throttle body to be built in a span of just one year. The company has also set its sight on Battery Management Systems (BMS). Averred Satarkar, “We have 75 per cent local business and 25 per cent international export so our focus is the local business, for that, we are prepared with BSVI products like throttle body which is in demand and in case of EVs the BMS.”

BSVI range

In the company’s BSVI product portfolio, the company is banking on the throttle body, electric purge valve, electric secondary air injection, oxygen sensor, electric fuel pump and fuel delivery module. Aligning the group strategy in line with the government’s ‘Make in India’ vision especially given the recent emphasis by Prime Minister Narendra Modi, on turning vocal for local, Satarkar expects continual demand over the medium to long term. “We believe in localisation. All our products are manufactured in India so all stakeholders are benefited with the surrounding ecosystem. While we source foreign technologies, they are tweaked for Indian conditions and local regulations like BSVI,” he stated. Adding that in case of the BSVI norms mandating the use of Electronic Fuel Injection (EFI) systems in two-wheelers, for instance, to replace carburettors, Satarkar drew attention to the in-house built, complete throttle body assembly. Attention was also drawn to the secondary air injection valve claimed to aid in the injection of fresh air into the exhaust stream and in turn, facilitate fuller combustion of exhaust gases.

In the company’s BSVI product portfolio, the company is banking on the throttle body, electric purge valve, electric secondary air injection, oxygen sensor, electric fuel pump and fuel delivery module. Aligning the group strategy in line with the government’s ‘Make in India’ vision especially given the recent emphasis by Prime Minister Narendra Modi, on turning vocal for local, Satarkar expects continual demand over the medium to long term. “We believe in localisation. All our products are manufactured in India so all stakeholders are benefited with the surrounding ecosystem. While we source foreign technologies, they are tweaked for Indian conditions and local regulations like BSVI,” he stated. Adding that in case of the BSVI norms mandating the use of Electronic Fuel Injection (EFI) systems in two-wheelers, for instance, to replace carburettors, Satarkar drew attention to the in-house built, complete throttle body assembly. Attention was also drawn to the secondary air injection valve claimed to aid in the injection of fresh air into the exhaust stream and in turn, facilitate fuller combustion of exhaust gases.

With BSVI norms, Satarkar cited the first-ever Evaporative Emission Control System (EVAP) standards for two- and three-wheelers. Known to prevent gasoline vapours from escaping into the atmosphere from the fuel tank and the fuel system, these systems are claimed to be low on maintenance. In case of a malfunction, however, it could translate to a vehicle failing the On-board Diagnostics (OBD) II plug-in emissions test. The purge valve, placed in the EVAP, for instance, controls the flow of fuel fumes from the canister to the engine. In case of a failure, the resultant vacuum leak can adversely affect the engine making it a critical component. It is known to change the car’s air to fuel ratio, causing rough idling, in turn, making it difficult to start the vehicle. Located between the carburettor and the engine crankcase, the reed valve is critical to the engine’s performance. In case of a failure, it can lead to engines finding it heard to accelerate. The engine stands to backfire on excess fuel being poured in.

With BSVI norms, Satarkar cited the first-ever Evaporative Emission Control System (EVAP) standards for two- and three-wheelers. Known to prevent gasoline vapours from escaping into the atmosphere from the fuel tank and the fuel system, these systems are claimed to be low on maintenance. In case of a malfunction, however, it could translate to a vehicle failing the On-board Diagnostics (OBD) II plug-in emissions test. The purge valve, placed in the EVAP, for instance, controls the flow of fuel fumes from the canister to the engine. In case of a failure, the resultant vacuum leak can adversely affect the engine making it a critical component. It is known to change the car’s air to fuel ratio, causing rough idling, in turn, making it difficult to start the vehicle. Located between the carburettor and the engine crankcase, the reed valve is critical to the engine’s performance. In case of a failure, it can lead to engines finding it heard to accelerate. The engine stands to backfire on excess fuel being poured in.

The company is also banking on the market pull for its variable displacement oil pumps built-in technical collaboration with German R&D company FMO Technologies (Trochocentric) GmbH. Entailing design, development and production of oil pump for passenger cars, commercial vehicles, stationary engines and transmission systems, the latter is crucial to control the oil pressure and volume in relation to the engine’s operating conditions. Claimed to offer a higher fuel efficiency by a margin of three to six per cent, the pump is also said to optimise heat transfer in the head and the pistons. The resultant power is said to reduce the formation of carbon deposits on turbocharged motors.

EV range

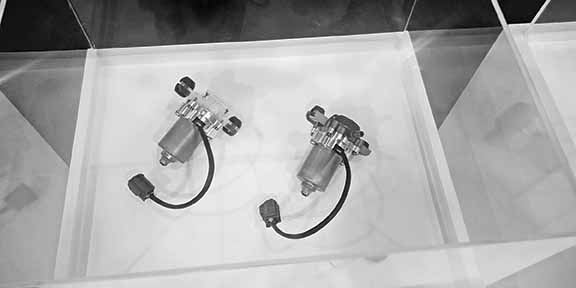

In the case of EVs, the company is banking on the BMS, motor and motor controller along with the brake system. The manufacturer offers electric water pumps claimed to reduce the engine load as a result of the master cooling circuit powered by motors. To bolster its EV product suite including the BMS and the battery pack, the company has also invested in ‘Ion Energy’, a startup to progress on in-house battery manufacturing. Among other key products in the EV suite are the axial flux motor and a motor controller claimed to be compact, robust and reliable. The company according to Satarkar is claimed to have built a unique architecture wherein the motor features a scalable and modular in design. Stacks of motors can further be used to scale up for multiple higher outputs as desired.

In the case of EVs, the company is banking on the BMS, motor and motor controller along with the brake system. The manufacturer offers electric water pumps claimed to reduce the engine load as a result of the master cooling circuit powered by motors. To bolster its EV product suite including the BMS and the battery pack, the company has also invested in ‘Ion Energy’, a startup to progress on in-house battery manufacturing. Among other key products in the EV suite are the axial flux motor and a motor controller claimed to be compact, robust and reliable. The company according to Satarkar is claimed to have built a unique architecture wherein the motor features a scalable and modular in design. Stacks of motors can further be used to scale up for multiple higher outputs as desired.

Future roadmap

In 2021, the European Union is expected to introduce new emissions regulations to limit the auto manufacturer’s fleet-wide average CO2 emissions by around 27 per cent, from 130 g CO2/km to 95g CO2/km. Advik is looking forward to it being introduced in India with the Corporate Average Fuel Economy (CAFE) norms in 2023. “The electric vacuum pump will help in the reduction of CO2,” said Satarkar. With clients in Bajaj Auto Limited, Honda Motorcycle & Scooters India Ltd., Suzuki Motorcycle India Ltd., Hero Honda Motors Ltd., Yamaha Motors India Ltd, Kawasaki Motors Corp and Lombardini India Pvt. Ltd., the company has set its sights on other segments like the four-wheeler segment. By 2025, Advik aims to attain a valuation of an estimated USD 300 million. If it succeeds, it will be on the back of expansion with existing customers, expansion to new customers with existing products and on the back of expanding to future relevant product categories proactively. ACI

Leave a Reply