The students of Mahindra University Hyderabad developed adaptive V2V chargers using bidirectional converters, and claimed to enhance EV charging flexibility, writes Richa Tyagi.

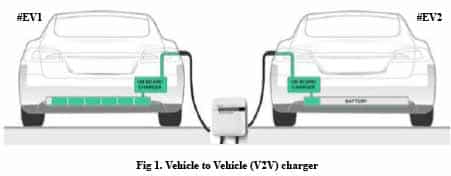

In today’s age, there is an ongoing debate on the usage of fossils and their alleged significant contribution to carbon emissions. With the transportation sector known to be the second largest consumer of fossil fuels, to restore the balance, Battery Electric Vehicles ( BEV) are the flavour of the season. However, a major challenge with the widespread adoption of EVs is the limited availability of charging infrastructure leading to longer charge times and inconvenience for users. A potential solution to eliminate this problem is to use Vehicle-to-Vehicle (V2V) chargers. V2V chargers in a way take the load of the grid and are positioned as the next best alternative to enhance the infrastructure.

The students of Mahindra University developed versatile and adaptive V2V chargers derived from bi-directional converters. Bi-directional converters’ significance increasing rapidly as these can be used for Vehicle-to-Grid (V2G) and Grid-to-Vehicle (G2V) applications. Various bidirectional converters are available for these types of applications in isolated and non-isolated topologies.

Non-isolated bi-directional converters

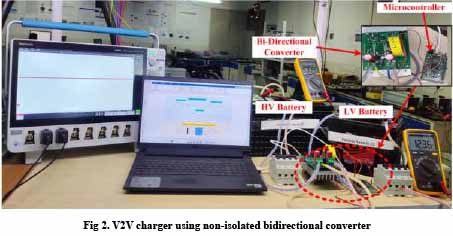

A non-isolated bidirectional converter, featuring a half-bridge configuration with two switches, inductors, and capacitors on either side, serves as an effective method for charging one EV with another. This converter is designed with fewer components, cost-effectiveness, and ease of operation when compared to alternative non-isolated topologies.

In the development and testing phase, this bidirectional converter simulated real-world EV scenarios positioning two batteries on either side of the converter to mimic the dual battery setup found in cars. The power flow is controlled using a current reference, allowing the high-side battery to charge the low-side battery and vice versa. “We conducted tests using our cars, employing the CCS protocol. When the CCS protocol is activated, it can acquire data from both vehicles,” explained Mohan Krishna, a Student at Mahindra University. For instance, if the second car has a lower battery level than the first car, the protocol will gather the total data from both cars. Subsequently, the first car will charge the second car,” he added.

DAB converter as V2V charger

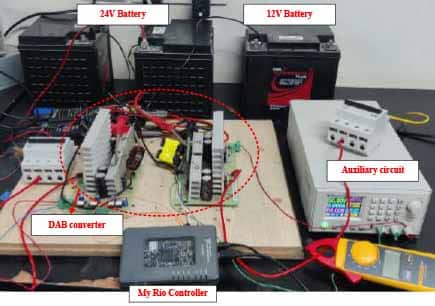

The V2V charger employs the Dual-Active-Bridge (DAB) topology to charge one EV using another. This topology proves advantageous for high-capacity chargers, facilitating quicker vehicle charging. This topology consists of two full bridges, an inductor, and a transformer, operating with two batteries set at 24V and 12V on either side of the converter, mirroring the setup of two vehicles. The converter’s functionality relies on phase shift operation—when the phase shift exceeds zero, the high-side battery charges the low-side battery. Conversely, a negative phase shift results in the low-side battery charging the high-side battery.

Versatility and compatibility

These V2V chargers are not limited to just four-wheelers. These chargers can also facilitate charging between different types of vehicles, including two-wheelers, and three-wheelers. This versatility ensures that the charger can be used in a wide array of scenarios, making it a comprehensive solution for the EV segment. “We developed these chargers to accommodate a wide range of output voltages, taking into consideration vehicles like the eVarito and Tata Nexon. For instance, the eVarito has an 80-volt battery, while the Tata Nexon has a 380-volt battery. These chargers can handle voltages from 80 volts to 380 volts, allowing it to switch seamless between different vehicles,” said Sreedhar Madichetty, Associate Professor at Mahindra University.

Vehicle-to-Grid (V2G) potential and cost efficiency

In addition to V2V charging, the developed technology also holds potential for V2G applications. Inspired by practices in Europe, where electricity tariffs vary between day and night, the V2G technology allows vehicles to charge when tariffs are low and discharge when tariffs are high, providing cost savings to the users. Moreover, during natural calamities or power outages, EVs can serve as backup power sources for critical facilities such as hospitals, providing ancillary services and enhancing resilience.

One of the key advantages of V2V chargers is their cost efficiency. Unlike traditional charging stations, which require extensive infrastructure such as input power filters, power factor correction devices, and other components, V2V chargers are much simpler. This simplicity translates to a reduction in costs, with estimates suggesting that only 20-30 per cent of the existing charging infrastructure’s cost is needed for these systems.

Key challenges

The most significant challenge in developing V2V chargers lies in the design and implementation of appropriate cables. Current cables are typically unidirectional, designed for Direct Current (DC) from the charging station with one open end and one closed end. For V2V charging, these cables need to be bidirectional, and capable of handling power flow in both directions. Additionally, integrating the communication infrastructure into a single, cohesive system presents a technical hurdle. “Overcoming these challenges will require collaboration with industry partners. If cable manufacturers can design and produce bidirectional cables with integrated communication capabilities, the development and deployment of V2V chargers will become much more feasible and efficient,” suggested Sreedhar. ACI

Leave a Reply