The Bosch pursuit of a technology-neutral powertrain development roadmap takes into consideration efficient combustion engines.

Story by: Ashish Bhatia

With inputs from Deven Lad

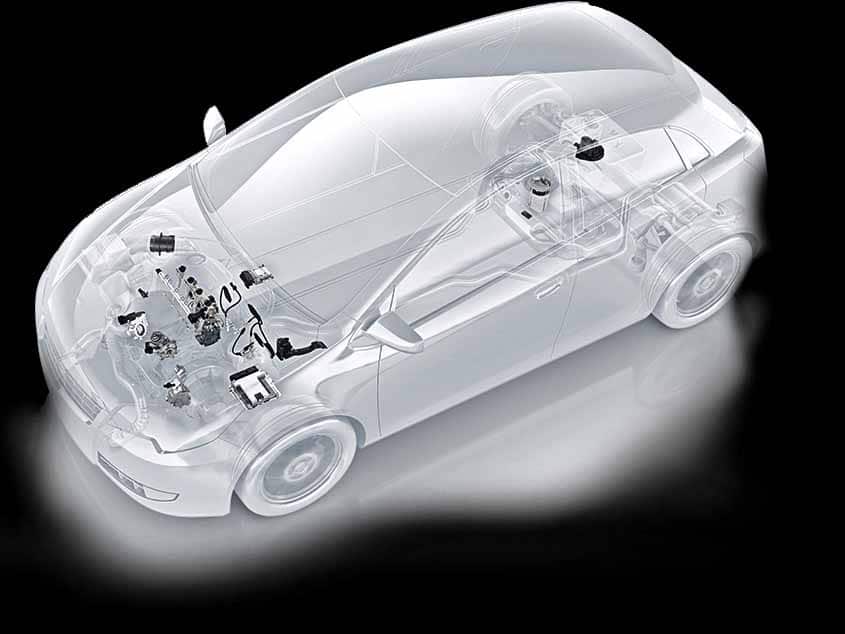

The Bosch Group is pursuing a technology-neutral powertrain development roadmap. As part of a long-term strategy, the technology and services provider wants to stick to a systematic approach to attain its ambitious climate goals. To realise its ambitions, the company is focusing on activities with the potential to offer sustainable mobility. Speaking at the Automotive Component Manufacturers Association of India (ACMA) – 60th Annual Convention, averred Soumitra Bhattacharya, Managing Director, Bosch India, “Internal Combustion Engines will command 75-80 per cent of the demand by 2030 with the rest coming in from electric vehicles.” “It is important that India benchmarks itself against the best. We need to be obsessed about standards to move forward. Unfortunately with jugaad being a way of life here, the standards are low,” he quipped. Bhattacharya made a case for the Groups’ broad technology offensive that sets out both a battery-electric path to sustainable mobility but equally considers efficient combustion engines besides setting a path for renewable synthetic fuels and fuel cells.

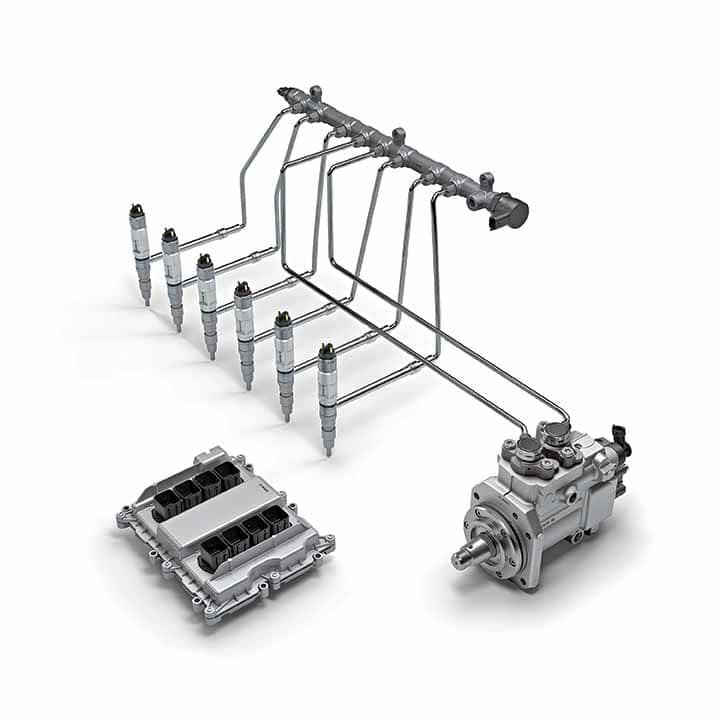

Powertrain product portfolio

Expect electrical solutions to complement the combustion solutions. Speaking at the Bosch Group Annual Press Conference in Germany, Volkmar Denner, Chairman, Board of Management of Robert Bosch GmBH said,” “As climate action is stepped up, electrical solutions will be limited in the near term to complementing the combustion solutions that have dominated up to now.” A Bosch market research estimates two out of every three newly registered vehicles in 2030 to run on diesel, with or without a hybrid option. It is the reason for Bosch to continue its investments in the development of highly efficient combustion engines. Bosch’s next-generation exhaust technology is claimed to have eliminated the NOx emissions from diesel engines completely citing the company’s individually conducted tests. Claimed Denner that Bosch is systematically refining the gasoline engine. This includes engine modifications and efficient exhaust gas treatment to bring down particulate emissions at a 70 per cent lower level compared to the Euro6 standard. Add to it, the company is confident of synthetic fuels making the combustion process carbon neutral. In a time of crisis, opined Denner, it would be a good proposition to offset such renewable synthetic fuels against the fleet consumption over-tightening the CO2 rules on the whole.

3R approach

In FY2020, Bosch limited made a provision of Rs.717 crore towards a 3R approach of restructuring, reskilling and redeployment initiatives. In line with the company’s efforts to capitalise on the inherent opportunities of mobility-related projects. Amounting to Rs.399 crore, the total investments by Bosch are attributed to the expansion of the Bidadi plant and Adugodi campus. The Bidadi plant inaugurated on July 17, 2020, is known to be a step towards making Indian manufacturing more efficient, more flexible and sustainable. Featuring the latest in Industry 4.0 solutions and carbon-neutral technology, it was built to boost competitiveness and meet the rising demand identified in the local market according to Denner. The Bidadi plant was built to act as a local hub for the company’s powertrain solutions and for the manufacture of common rail single cylinder pumps and high-pressure rails among other automotive products. Known to have been the largest relocation project undertaken then, it had the former Adugodi site being converted with the ambition of making it the largest technology campus outside Germany.

According to Bhattacharya, Bosch in India is adapting to the current market developments with measures to manage resources and enhance operational efficiencies. As per a press statement, the company has undertaken several restructuring and transformation projects to secure future profitability and growth. The total revenue of Bosch Limited’s Mobility Solutions Business sector decreased by 23.7 per cent in the quarter ending March 31, 2020. Here, the total revenue of the powertrain division declined by 29.5 per cent.

Fiscal 2021 outlook

On the outlook for fiscal 2020-21, the company according to Bhattacharya has been affected severely. “As a leading automotive technology company with 80 per cent of our revenues driven through mobility business, we have been affected severely,” he expressed. “ The auto sector as a whole will take four to five years to return to 2018-19 levels,” he opined. Committing to being a technology agnostic partner to customers, government and stakeholders at large, Bosch since 2017, is known to have executed 79 BSVI projects in passenger cars and commercial vehicle segments with major Original Equipment Manufacturers (OEMs). In India, the company is expected to continue investing in competence development and developing solutions, designed in India for India. At the group level, the company anticipates challenges for the global economy in the current business year. Stated Denner, “To achieve at least a balanced result, we will make a supreme effort.” “Although, other issues are currently in the spotlight, we must not lose sight of the future of our planet,” he concluded. ACI

Types of exhaust-gas sensors

To meet the needs of a reliable analysis of the exhaust-gas composition, the basis of exhaust-gas treatment, vehicles must be equipped with different sensors known to be installed in the exhaust duct. The sensors in turn are integrated into the onboard diagnostic system. Bosch offers five types of exhaust-gas sensors.

Nitrogen-oxide sensors

Using a resilient and heat-resistant ceramic sensor element, the amount of nitrogen oxide (NOx), downstream of the Selective Catalytic Reduction (SCR) catalytic converter is measured. In some engines, the NOx sensors are included upstream of the catalytic converter. The sensors control the amount of AdBlue injected into the catalytic converter for SCR inturn to reduce NOx thus making them an important aftermarket inclusion.

Using a resilient and heat-resistant ceramic sensor element, the amount of nitrogen oxide (NOx), downstream of the Selective Catalytic Reduction (SCR) catalytic converter is measured. In some engines, the NOx sensors are included upstream of the catalytic converter. The sensors control the amount of AdBlue injected into the catalytic converter for SCR inturn to reduce NOx thus making them an important aftermarket inclusion.

Exhaust-gas temperature sensors

The exhaust-gas temperature sensors can be installed across locations within the exhaust duct of diesel and gasoline engines. The sensors measure the temperature of exhaust gases. An electric voltage signal is sent to the Engine Control Unit (ECU). In diesel engines, they monitor the temperature of the particulate filter in turn contributing to the compliance with emission limits and fuel efficiency. They help protect the catalytic converters and turbochargers.

The exhaust-gas temperature sensors can be installed across locations within the exhaust duct of diesel and gasoline engines. The sensors measure the temperature of exhaust gases. An electric voltage signal is sent to the Engine Control Unit (ECU). In diesel engines, they monitor the temperature of the particulate filter in turn contributing to the compliance with emission limits and fuel efficiency. They help protect the catalytic converters and turbochargers.

Particle sensors

Particle sensors analyse the amount of soot particle in diesel emissions using resistance measurement. The control unit based on the analysis studies the functionality of the diesel particle filter. Ahead of each measurement, the sensor element is known to be regenerated by heating it up in order to standardise sensor condition for all measurements.

Particle sensors analyse the amount of soot particle in diesel emissions using resistance measurement. The control unit based on the analysis studies the functionality of the diesel particle filter. Ahead of each measurement, the sensor element is known to be regenerated by heating it up in order to standardise sensor condition for all measurements.

Differential-pressure sensors

Differential-pressure sensors

Differential-pressure sensors measure the pressure difference of the particle sensor. It allows a study of the condition of the particle filter in order to trigger the demand-based and fuel-saving particle filter regeneration (self-cleaning). They are also used to control low-pressure exhaust gas recirculation.

Lambda sensors

Lambda sensors determine the amount of oxygen contained in exhaust gases. It helps the ECU determine optimal fuel efficiency to be injected in the combustion chamber. Used in gasoline, diesel and gas engines, they offer high measurement accuracy and are said to actively support engine efficiency and effective exhaust gas treatment. New lambda sensors are claimed to offer a 15 per cent fuel saving over the worn-out sensors.

Lambda sensors determine the amount of oxygen contained in exhaust gases. It helps the ECU determine optimal fuel efficiency to be injected in the combustion chamber. Used in gasoline, diesel and gas engines, they offer high measurement accuracy and are said to actively support engine efficiency and effective exhaust gas treatment. New lambda sensors are claimed to offer a 15 per cent fuel saving over the worn-out sensors.

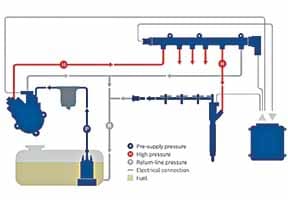

Denoxtronic

An exhaust gas treatment system, it is found largely in diesel vehicles. The system injects AdBlue into the exhaust duct. Together with SCR, it allows the conversion of NOx into water and nitrogen.

An exhaust gas treatment system, it is found largely in diesel vehicles. The system injects AdBlue into the exhaust duct. Together with SCR, it allows the conversion of NOx into water and nitrogen.

Efficient Weichai truck diesel engine

Bosch and engine manufacturer Weichai Power of China set out to increase the efficiency of the latter’s heavy-duty commercial vehicle engines two years ago. After two years, the two are claimed to have attained a big leap in engine technology. They have successfully increased the engine efficiency to 50 per cent from an average of 46 per cent thermal efficiency level. Averred Dr Volkmar Denner, chairman of the board of management of Robert Bosch GmbH, “In increasing the efficiency by four percentage points, we have jointly reached a new milestone. Even though the diesel engine is nearly 130 years old, its development continues.” Of the opinion that for heavy loads to be transported over long distances, the diesel engine will remain the preferred choice for the foreseeable future, Bosch and Weichai are working to steadily refine this technology. Bosch and Weichai, China’s largest manufacturer of engines for commercial vehicles first began their strategic alliance in 2003. Over 17 years, the two companies have pooled their strengths and expertise in diversity initiatives. For instance, to supply the Chinese market with powerful, energy-efficient, and eco-friendly diesel engines. The alliance also extends to the mobile fuel cell and driver assistance systems, and beyond mobility to domains like Industry 4.0 for connected and digitised factories.

Bosch and engine manufacturer Weichai Power of China set out to increase the efficiency of the latter’s heavy-duty commercial vehicle engines two years ago. After two years, the two are claimed to have attained a big leap in engine technology. They have successfully increased the engine efficiency to 50 per cent from an average of 46 per cent thermal efficiency level. Averred Dr Volkmar Denner, chairman of the board of management of Robert Bosch GmbH, “In increasing the efficiency by four percentage points, we have jointly reached a new milestone. Even though the diesel engine is nearly 130 years old, its development continues.” Of the opinion that for heavy loads to be transported over long distances, the diesel engine will remain the preferred choice for the foreseeable future, Bosch and Weichai are working to steadily refine this technology. Bosch and Weichai, China’s largest manufacturer of engines for commercial vehicles first began their strategic alliance in 2003. Over 17 years, the two companies have pooled their strengths and expertise in diversity initiatives. For instance, to supply the Chinese market with powerful, energy-efficient, and eco-friendly diesel engines. The alliance also extends to the mobile fuel cell and driver assistance systems, and beyond mobility to domains like Industry 4.0 for connected and digitised factories.

Leave a Reply