In a Messe Frankfurt hosted webinar, stakeholders of the automotive industry shared the roadmap to capitalise automation in manufacturing.

Story by: Deepti Thore

Messe Frankfurt India recently concluded a webinar titled ‘Future of Factory Automation in Automotive Manufacturing’. The stakeholders of the automotive industry got together to lay the roadmap of future factory automation. Capitalising automation in the context of automotive manufacturing, the session drew attention to the industry beginning to look at it as an asset in the balance sheet rather than an expense in the income statement. The role of Industry 4.0, the introduction of next-generation digital technologies, roles and contributions of different stakeholders took centre stage. Drawing attention to the strengths, weaknesses, opportunities and threats, machinery safety, services and solutions were cited as crucial to developing best manufacturing processes. With the backdrop of social distancing and limited manpower deployment in the aftermath of the pandemic, mentioned Sudhanshu Kantoor, GM – Product Management, Pepperl+Fuchs that automation solutions would cater to these limitations. “They would aid the human workforce to make their life easier. These solutions also help reduce the inventory and enable remote monitoring and remote diagnostics.” Kantoor further stressed on focus areas including component detection, collision avoidance, positioning, identification, material handling and IO link interface deployed point-to-point serial communication protocol used to communicate with sensors and or actuators pertaining to factory applications.

Business Threats

According to Ninad Deshpande, Head-Marketing & Corporate Communications, B&R Industrial Automation, for maintaining the health of any manufacturing plant, defining KPIs and monitoring them is crucial. Deshpande stressed on how quality was by far one of the most important aspects in terms of service or product. “For any factory or factory manager to derive the required output they eventually need to look at the productivity,” he said. Higher Overall Equipment Effectiveness (OEE), better availability of the machine or lines and high-quality levels are some of the factors the company should look at to overcome the new set of business challenges. The downtimes, however, need to be lowered for any factory operation, he beamed. Added Deshpande that in order to restrict the investment or keep maintenance levels low, the need of the hour was for factories to focus on asset maintenance, monitoring, remote diagnostics to name a few. “Future factories will enable industries to increase their competitive advantage or become more competitive or efficient, productive and eventually more profitable. This is what a future factory holds for everyone,” he opined.

Predictive Maintenance

Future factories can be built on the back of a combination of various technologies or solutions applied on the shop floor, IT and the cloud. Some of these include scalability, digital twin, web-based HMI and diagnostics, open connectivity, IIOT, edge architecture, predictive maintenance and mass customisation. Speaking about how factories can leverage these turn more collaborative, Deshpande stressed on the need to ensure collaboration between multiple vendors on the shop floor on the operational front as well as on the IT front if factories were to evolve. Given that any automotive factory has around 100-1000 machines, automation vendors, it was recommended be kept the same to avoid a seamless flow of information. Especially to avoid maintenance side issues.

To operate future factories from remote locations, deliverables and raw materials have to come in time. Similarly, the lines and the machines need to work round the clock with minimum interference from different entities. Here digital transformation is expected to play a crucial role. Predictive maintenance solutions were said to be gaining prominence. For example, if a bearing in a machine is about to fail in a couple of weeks, the factory can get the spare parts dispatched in advance and the maintenance team can then replace it by doing a planned shut down rather than having an unplanned shutdown with the bearings failing and the production coming to standstill.

Component Detection

Briefing on the importance of precise component detection, the importance of the presence and absence of a target, proper orientation, quality checks and quality inspections were discussed. Drawing attention to the harsh working environment making sensors susceptible to damage over a period of time, the panellists focused on the different available technologies for aiding reliable and precise monitoring. “There are stainless steel housing sensors with stainless steel sensing faces made from a single metal housing. These sensors are capable of withstanding high mechanical impacts thereby giving a longer life to the operation of normal sensors,” explained Kantoor. With the availability of coated sensors claimed to offer insulation from high magnetic fields, added Kantoor that the robust sensors could be deployed in many lines sans problems thereby helping in curbing the instances of failures.

In terms of different sensing solutions, multiple targets available in the automotive manufacturing industry were touched upon. Classified broadly as ferrous or non-ferrous materials, the latter need to be sensed in an equidistant manner. “There is a need to reduce the switching distance on the field every time there is a change in the target. There are special sensors which can detect all types of ferrous material from the same sensing distance,” stated Kantoor. For instance, sensors are known to work precisely on sensing an old metal target. However, a change in target from mild steel to copper or brass, as per the ferrous content inside the sensors calls for recalibration. It is here that the special sensors are said to eliminate the need for any recalibration including mounting.

Quality control

Manual inspections are more prevalent. Here the introduction of the automated inspection was said to have an upper hand. Using a unique combination of light section sensors with the inbuilt 2D vision, the inspection works such that a laser beam falls on the component to capture a 2D profile image inturn. The mother part and the child part are welded but since they are of the same colour and contour it is difficult for the conventional system to check the quality of welding for instance. It is here that automated inspections were agreed upon as an efficient mechanism to reduce the downtime.

Anti-collision mechanism

Sensing solutions were talked off as a robust way to ensure both personal and machine safety, especially in automated areas. Of the opinion that it guarantees smooth processes on conveyors, presses and lifter, it was talked off as a crucial inclusion in future factories. Take, for instance, the automotive shop floor, where automotive parts or structures can be found moving on an Electrified Monorail Systems (EMS) conveyor. In the case of the latter, it is a possibility that collisions occur on certain bends. Here the role of Pulse Ranging Technology (PRT) scanners were highlighted. With a scanning range of eight metres and coverage span of 88 degrees and a set of Ultra infrared 11 LEDs, the scanner found a mention.

Optical-based identification systems

Identification is especially important to engine assemblies, monorail conveyors and overhead conveyors. The optical-based identification systems or RFID based systems were spoken of in the context of engine assemblies, body shops and high-temperature areas like paint shops. With the capability of RFID enabled access control system to aid in attendance, social distancing and reduced work deployment, the diverse range of such systems with a reading range of up to six metres was spoken of in the session. Direct Part Making (DPM), one-dimensional and two-dimensional barcode reader incorporated in a single system, with Optional Character Recognition (OCR) numbers were also mentioned. Identification scope was expanded from being limited to components to finding application in other feeder lines.

Industry 4.0

Industry 4.0 enhances interconnectivity of devices thus making the devices connect with each other and to higher levels of ERP systems or SAP. IO link was spoken off highly with its capabilities of facilitating bidirectional communication. For instance, it was said, on the field, the health of field devices could be monitored with the help of sensors and the actuators to check the status. IO technology, it was agreed upon, facilitates a higher degree of control on field devices. The generated parameters further allow a feedback mechanism to route it to the ERP system and or the cloud with the capabilities of remote access made possible through the OPC Unified Architecture (OPC UA). A machine to a machine communication protocol for industrial automation is developed by the OPC Foundation. Remote automatic parameter setting was deemed as an added advantage. OPC UA TSN is a low cost open international standard independent software with plug-and-produce features and integrated security system. It has got inbuilt security and certificate exchange. The factory today can leverage the user authentication inbuilt into its protocol and build a future factory by reducing the cost for horizontal and vertical communication.

Industry 4.0 enhances interconnectivity of devices thus making the devices connect with each other and to higher levels of ERP systems or SAP. IO link was spoken off highly with its capabilities of facilitating bidirectional communication. For instance, it was said, on the field, the health of field devices could be monitored with the help of sensors and the actuators to check the status. IO technology, it was agreed upon, facilitates a higher degree of control on field devices. The generated parameters further allow a feedback mechanism to route it to the ERP system and or the cloud with the capabilities of remote access made possible through the OPC Unified Architecture (OPC UA). A machine to a machine communication protocol for industrial automation is developed by the OPC Foundation. Remote automatic parameter setting was deemed as an added advantage. OPC UA TSN is a low cost open international standard independent software with plug-and-produce features and integrated security system. It has got inbuilt security and certificate exchange. The factory today can leverage the user authentication inbuilt into its protocol and build a future factory by reducing the cost for horizontal and vertical communication.

Industrial Internet of Things

In an automotive sector, when the engine or the entire chassis is being transmitted on a railing or car trains, a lot of vibration is recorded. If these vibrations are not taken care of, the bearing, the chains or the entire shafts stand to collapse leading to a high downtime. Today data points can help monitor the vibrations, in turn providing a high degree of a predictive maintenance solution in such operations. Lines cab have become more efficient thus. The session called for stakeholders of the industry to map relevant techniques, conduct feasibility studies, prioritise technologies and ultimately create a clear actionable road map.

Machinery safety services and solutions

Talking about automotive machinery safety and solutions, Girish Alawe, Head-tec. Nicum, Machine Safety Consulting, Schmersal India Pvt. Ltd., focused on topics such as smart safety devices, Industry 4.0, light curtains with Bluetooth, serial diagnostic interface, safety controller and safety field box in the session. Alawe drew attention to the adaptable ISO standards in Bureau of Indian Standards (BIS) which can happen in the near future. Citing an ongoing discussion between the BIS and the ISO for the adoption of International Organization for Standardization (ISO) machinery standard in India, Alawe informed of 32 standards being identified and taken into consideration by BIS. “These standards have already been finalised in 2018 and have been sent to Indian ministry for final approval. In future, the machines will need to have the qualification of these BIS standards,” he claimed. As per the analysis carried out by Schmersal India, procedures like emergency stop as per the full specific machinery safety standards, two-hand control, and safety devices like safety mats, door interlocking guards could drive the change. Robots have gained popularity among manufacturers. The door interlock is one such form of robot application with fencing around it creating a boundary for intervention. Safety light curtains, safety sensors, emergency stop beside other safety controllers are gaining prominence too, it was said.

Safety components and controllers

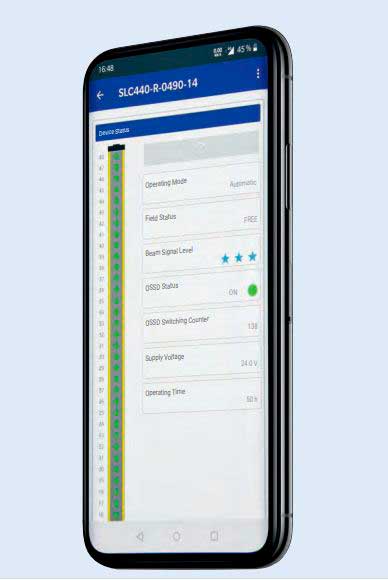

Safety Light Curtains ( SLC ) is a type of safety application which protects personnel from injury and machines from damage by creating a sensing screen that guards machine access points and perimeters. If the curtains are connected via Bluetooth, they provide all the data through an app. such as SLC assist’ to check whether the curtain is aligned or not and whether any of the beams are disturbed. The app. basically helps to monitor the curtains and also provides details about the operating modes, the status of the output, the status of the protective field, which of the beams are disturbed etc. With preventive maintenance, the curtains stand to be replaced in the near to medium term. At the supplier and end-user side, in case of multiple complicated wiring on a field from long distances to control panel, SD-adapter was spoken of as a good option.

If one has to reduce the wiring from the machine or reduce the number of cabling parts and y connectors, the serial diagnostic technology was cited as an apt option to connect multiple devices to a central controller. It can connect up to 120 devices. The field boxes which are connected to controllers and a master controller ensure data availability on the gateway. Controllers are another important aspect of any logic or machine safety. These safety controllers connect to the master controller and transmit the data to the Programmable Logic Controller (PLC). When they transmit the data to the master PLC, it is of utmost importance that they keep to safety standards in accordance with ISO 13849-1 safety standard. ACI

Leave a Reply