By: Daniel Paterra, President and GM, BorgWarner Thermal Systems

Thermal Management systems are more critical than ever in today’s diesel engines. Stringent emission regulations and increasing power density are driving engine designs that run hotter and reject more heat. By optimising key components of the thermal system—including the fan, fan drive and coolant pump—BorgWarner engineers have successfully turned a challenge into an opportunity to reduce emissions and improve fuel economy. In back-to-back tests, an optimised cooling system with variable-speed fan drives and coolant pumps improved fuel economy up to 5% over conventional technologies.

In heavy-duty engines, only about 40-45% of fuel energy results in moving the truck. The rest is wasted little by little in parasitic losses—through the friction of belts or pulleys, drag on bearings and running auxiliary systems when they are not necessary. Making every system more efficient optimises the entire engine.

Precise temperature control—providing the right amount of cooling at the right time—improves engine efficiency. Using calibrated software to communicate with the engine’s electronic control unit (ECU), BorgWarner’s variable speed Visctronic fan drives continuously respond directly to engine cooling needs. Reducing the high fan speed spikes common in conventional systems eliminates parasitic losses and results in more available horsepower, which leads to better fuel economy and lower emissions.

Using a similar concept, BorgWarner has developed variable-speed coolant pumps that work with the ECU to manage the pump’s impeller speed based on coolant temperature instead of engine speed. Since the coolant pump runs only when needed and only at the speed needed, the average overall pump speed is significantly lower. Depending on the duty cycle, the reduction in parasitic losses can improve fuel economy up to 1.5%.

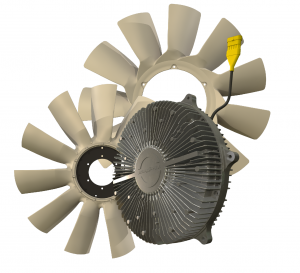

While electronically controlled fan drives and coolant pumps have garnered a lot of attention, recent advancements in fans also increase engine efficiency. In Class 8 commercial truck applications, a 32 in. diameter fan with 11 blades is common. However, when the fan drive is disengaged, the fan blades can block the air flowing through the radiator. For applications with limited peak cooling demands, BorgWarner has developed fans with fewer blades featuring optimised geometry to provide sufficient cooling power without impeding airflow.

In many applications, fans are enclosed within a shroud to direct air from the radiator. The gap between the fan and shroud results in air recirculation from behind the fan to the front of the fan. BorgWarner’s patented shroud guide vane ring is engineered to redirect air and maximize airflow, resulting in as much as a 10% improvement in fan efficiency and performance when compared with standard installations.

Optimised thermal management is the key to improved vehicle efficiency. Working closely with engine designers, BorgWarner shares its expertise in controls and systems integration as well as fan design to help calibrate the entire cooling system for optimal engine performance.

Leave a Reply