Text & Photos: T Murrali

Auto component maker Rajsriya Automotive Industries Private Limited has recently inaugurated its powder coating facility at its Sriperumbudur plant. Situated at the premises of plant 6, the powder coating factory was inaugurated by the Managing Director of Wabco India, P Kaniappan.

Speaking to Auto Components India, the Managing Director of Rajsriya Group, P S Govindachari said the company has garnered expertise in power coating for more than 15 years with its plants in Hosur. Sensing that powder coating operations on a large scale was not prevalent in Chennai, Rajsriya Automotive has invested about Rs 15 crore in setting up this fully automated plant. The new facility initially will have a minimum workforce confined to only loading and unloading operations. With an installed capacity to coat up to 30,000sqft a day the plant will cater to the requirements of Wabco India, Daimler India Commercial Vehicles (DICV) and Johnson Control & Automotive Limited.

The Sriperumbudur plant, originally owned by Chennai CNC, was bought by Rajsriya Automotive in 2012 for an investment of about Rs 30 crore. It had two sheds manufacturing sheet metal parts for Wabco and a few other customers. With Rajsriya adding another shed in the premises for its power coating operations, it has become an integrated manufacturing facility offering end-to-end solutions to customers.

At present, the automation level at the powder coating plant is around 70% and gradually it will become 100% with manual operations confined to only supervision and control stations. It is already supplying 47 components to DICV and supply of about 35 more components are under negotiation. These components are meant for the domestic OEMs and exports as well.

As of now Rajsriya Automotive has 9 plants (7 in Hosur and 2 in Chennai) catering to a band of customers including TVS Motor Company, which is the largest customer. It is currently setting up a new factory in Nalagarh in Himachal, which will be its 10th plant. Coming up at an investment of Rs 10 crore the new plant will supply pressed parts and assemblies to TVS Motor Company. It will be up and running before end of the current fiscal, said Govindachari. The plant will also be looking at catering to customers in the northern region.

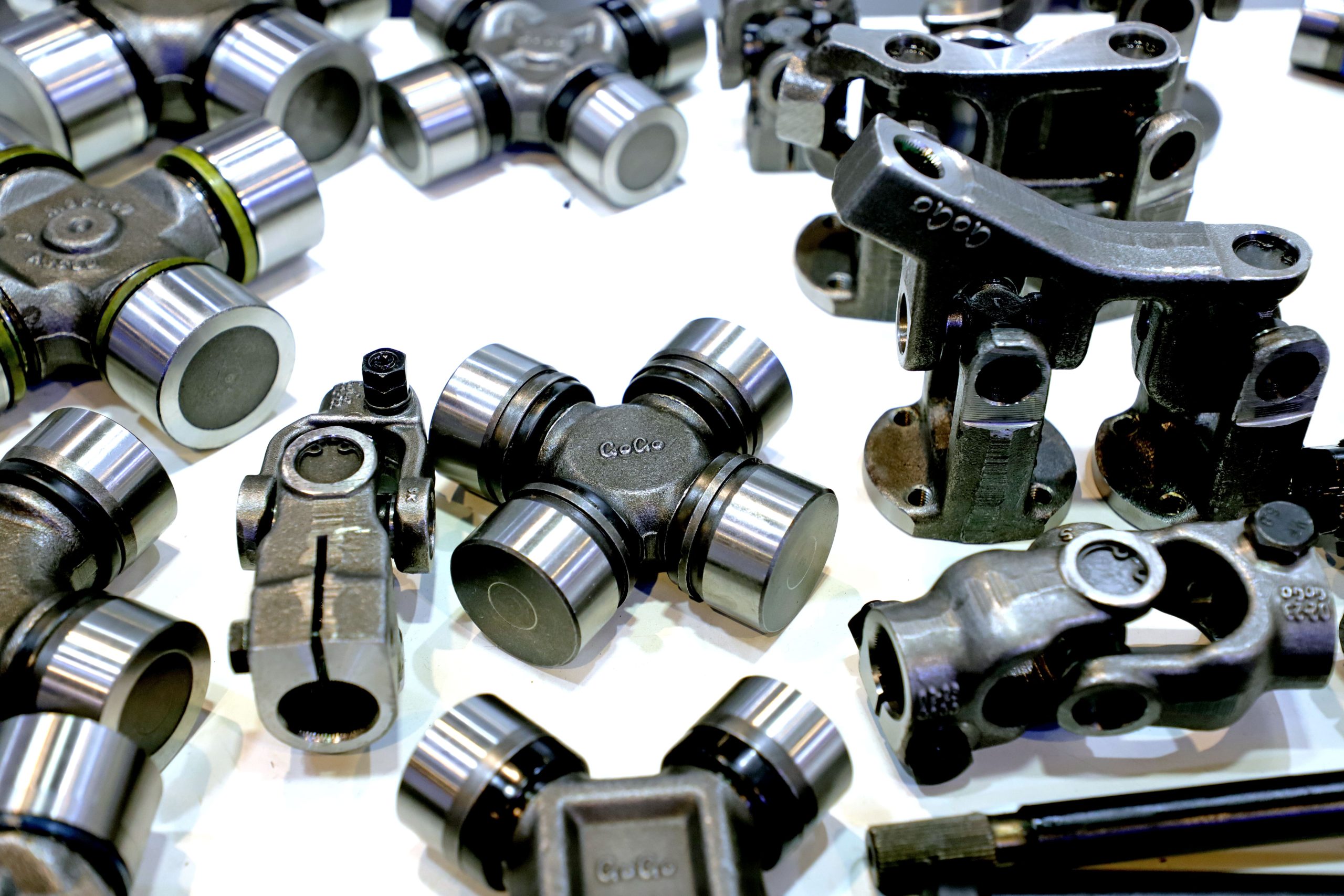

About 80% of the products manufactured by Rajsriya Automotive goes to TVS Motor Company. For the 2-wheeler maker, it makes several parts including mudguard, steering column parts, muffler, heavy duty carrier etc. In addition, the company also caters to the requirements of Delphi-TVS, T I Cycles, Tafe, Mando, Takata, Brakes India, Lucas-TVS and Rane NSK. It also supplies starter motor assembly to a leading Tier-1 company. Soon, Rajsriya Automotive will commence manufacturing filter bowls for Delphi-TVS, as an import substitute.

The company also exports to Germany and the US, to a few customers that include GE, Saginaw, Bell & Howell etc. Besides, it also exports to Suzuki in Japan.

Sensing Opportunities

Rajsriya Group is an automobile ancillary parts manufacturing company engaged in design, manufacturing and assembly of a wide range of products used in automotive vehicles such as two-wheelers, three-wheelers, passengers cars, and light and heavy commercial vehicles. Sensing opportunities in auto electricals, the company was founded by Meera Chari in the year 1977 in a small shed in Chennai manufacturing wire wound resistors; later on it shifted to an industrial shed in Arumbakkam. Over the years it grew by identifying emerging potential and diversified its manufacturing to automobile and electronic components and sub-assemblies with two more industrial sheds in Chennai. It further diversified into two-wheeler components and sub-assemblies in the year 1994, setting up two factories in Hosur.

At present Rajsriya Group has two entities – Rajsriya Automotive Industries Private Limited and Autopluss Electrical Components Chennai Private Limited. The group reported turnover of Rs 400 crore in 2013-14.

Leave a Reply