Text & Photos: T Murrali

The Chennai-based Super Auto Forge Private Limited (SAF) is all set to march ahead into the future leveraging its core competence in metal forming. The company has been consolidating its bouquet of products for some time and now it is focusing on 3 product lines such as drive shafts, brakes and steering & suspension parts. Till the early 1990s the company was manufacturing parts for almost all major assemblies and had more than 60 customers in the domestic market catering to the who’s who of the auto industry.

The company, a pioneer in cold forged components in the country, is hoping to cross the Rs 500 crore mark as turnover in 2015-16 from Rs 305 crore in 2011-12. During this period the company has invested Rs 88 crore. These investments will help SAF expand capacity by about 30% eventually achieving its sales target says the Managing Director of the company S Seetharaman. The investments are for inducting next generation machines that are higher in productivity while also enhancing quality.

The main activities of the company include cold forming, cold extrusion, precision warm forging, precision finish machining, heat treatment, surface finish treatment and assembling sub-systems. It handles both ferrous and non-ferrous materials since its foray into aluminium warm forging in 2005.

At present, SAF has a cumulative capacity of 500 tons of aluminium forgings and about 2,000 tons of steel forgings. It also hopes to enhance capacity by resorting to automation and technology upgradation, not augmenting manpower. The company that is by far the largest cold forge parts manufacturer in the country in terms of value and volumes, has 3 plants in Chennai – Kolapakkam, Thirumudivakkam and the Madras Export Processing Zone (MEPZ) near Tambaram. It has an exclusive plant at Ekkattuthangal for manufacturing Special Purpose Machines, Testing machines and Automated Assembly lines. SAF has offices and warehouses in North America and Europe.

At present, SAF has a cumulative capacity of 500 tons of aluminium forgings and about 2,000 tons of steel forgings. It also hopes to enhance capacity by resorting to automation and technology upgradation, not augmenting manpower. The company that is by far the largest cold forge parts manufacturer in the country in terms of value and volumes, has 3 plants in Chennai – Kolapakkam, Thirumudivakkam and the Madras Export Processing Zone (MEPZ) near Tambaram. It has an exclusive plant at Ekkattuthangal for manufacturing Special Purpose Machines, Testing machines and Automated Assembly lines. SAF has offices and warehouses in North America and Europe.

The company is predominantly into the passenger car segment, has a small presence in commercial vehicles and nil in the 2-wheeler segment. Focused attention is being paid to develop more ‘non-automotive’ parts, says the Joint Managing Director of SAF, S Muralishankar.

The company is predominantly into the passenger car segment, has a small presence in commercial vehicles and nil in the 2-wheeler segment. Focused attention is being paid to develop more ‘non-automotive’ parts, says the Joint Managing Director of SAF, S Muralishankar.

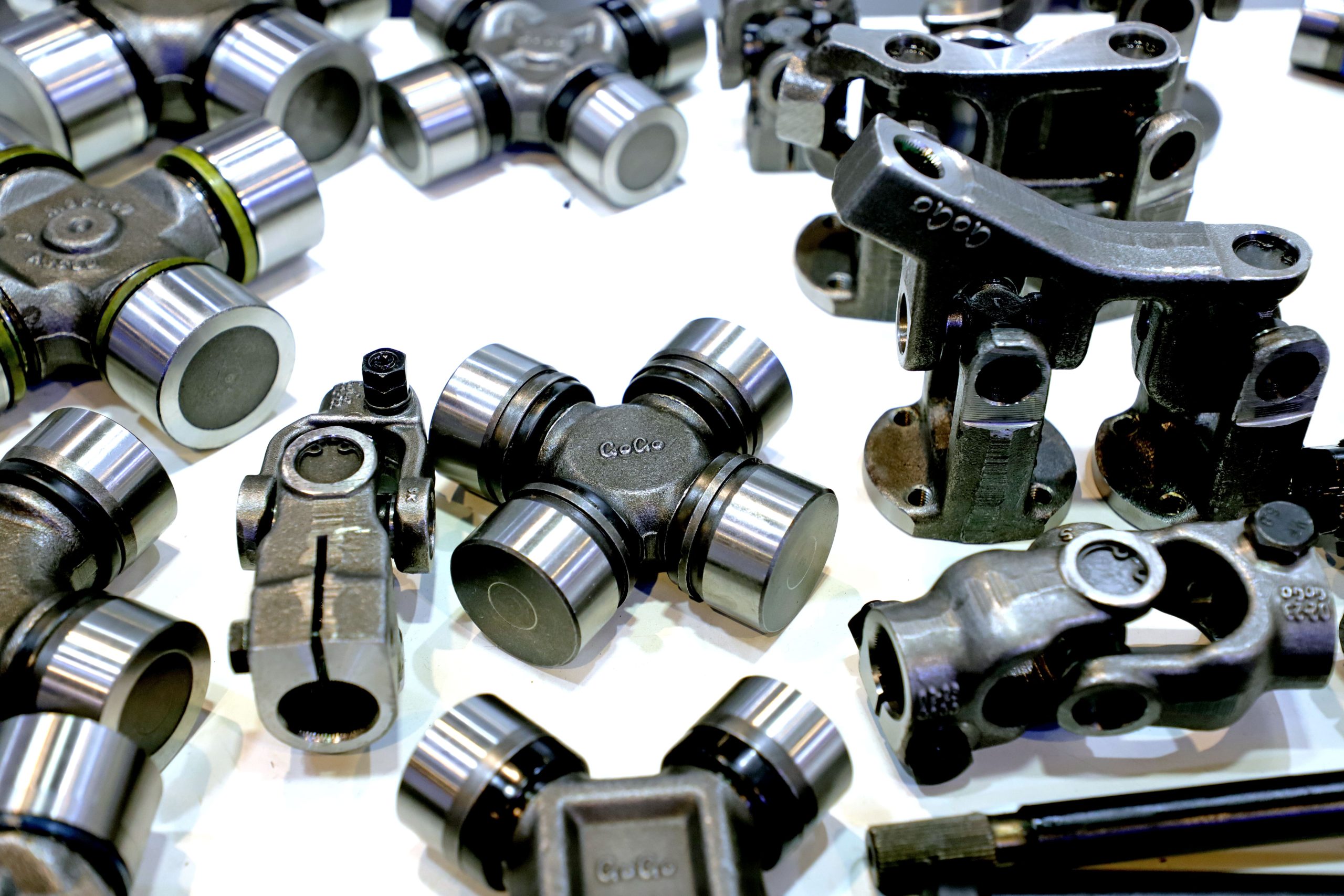

The company currently makes a variety of parts for suspension, steering, braking system and constant velocity joints at its Kolapakkam plant. At Thirumudivakkam it makes a variety of plungers for master cylinders and booster systems. In this plant the company also manufactures large quantities of aluminium yokes, brackets and parts for heavy electrical industries. The plant at MEPZ focuses on production of assembled ball joints to Chrysler and General Motors, through their major module suppliers. Approximately 60% of its sales are exported to Tier-1 companies like TRW Automotive, Bosch, ZF Lemforder, Neapco etc. Efforts are also being made to balance supplies between USA, Europe and Asia, indicates the Director of the company, S Ravishankar.

The debt-free company has recently inducted a ‘Parts Former & Header’ machine costing Rs 23 crore. This can make cold formed parts from steel coils of up to 33mm diameter. During a short tour of the plant, Muralishankar explained that the 5-station machine (a combination of 5 forging presses in sequence) can make about 100 components in fully finished condition in a minute.

SAF has finalised on another machine that can take up coils up to 44mm diameter, which will have 6 stations. The progressive or sequential forging presses eliminated the annealing to overcome the work hardening (hardening on account of difference in temperature between processes) in the conventional forging. The new generation machines helped the company eliminate many presses and CNC machining centres. Besides, the throughput of the component has been reduced from about 3 days to a few minutes. In addition, it will also substantially reduce the number of input sizes of material.

To finish the components the company has a dedicated cell for high volume parts and a flexible line for low volume parts. It has more than 100 CNC turning centres and 20 vertical machining centres in addition to special purpose and conventional machines. These are adequately supported by heat and surface treatment facilities. The company which has no collaboration for foreign technology has an ‘Advanced Technology’ development division that utilises FEA and other ‘Simulation’ techniques for development of critical and complex parts, mentions Ravishankar.

To finish the components the company has a dedicated cell for high volume parts and a flexible line for low volume parts. It has more than 100 CNC turning centres and 20 vertical machining centres in addition to special purpose and conventional machines. These are adequately supported by heat and surface treatment facilities. The company which has no collaboration for foreign technology has an ‘Advanced Technology’ development division that utilises FEA and other ‘Simulation’ techniques for development of critical and complex parts, mentions Ravishankar.

To support its requirements the company has an in-house tool room; it is augmented with CAD/CAM and other software that are globally used by the forging companies in the developed markets. The idea is to remove human intervention for increasing accuracies. Recently, it has commissioned a ‘Vacuum hardening’ machine for tool heat treatment. It helps the company to maintain quality and increase the yield from every tool. This completes the spectrum of its requirement to make forgings – right from conceptualising till the finished product is shipped. Seetharaman attributes the success of the company to its highly experienced managerial resources and process capabilities of the entire value chain, with more emphasis on machines and automation built in-house.

The company started Special Purpose Machine building operations in 2005 and thereafter it contained the procurement of standard machines. The objective is to reduce manufacturing cycle time, enhance quality and safety, besides containing rejections. The company has facilities to fully recondition imported used machines.

Diversification

SAF was predominantly focusing on exports since 1998. As it was hit badly by the global slowdown in 2008, it diversified into the non-auto sector the same year. Under this division it makes levers, electrical contacts, cylinders, flanges and plates primarily for the heavy electrical industry. Alongside, it is working on developing products for industrial applications. Already it is catering to the requirements of compressor makers. In order to derisk the operations from over dependence on automotive parts, SAF is targeting to have 25% of the total revenue from non-automotive segment. Next in reckoning for the company is aerospace, affirms Seetharaman.

In 2013-14, sales from North America accounted for 51%, Europe 17% and the rest from the domestic market. Though the same trend continues now, it may change in future as domestic volumes pick up.

Directed Source

The company has been a ‘directed source’ for suspension ball joints for Chrysler and General Motors since 2006. It may be noted that SAF ships over 6 million ball joints annually for these two companies. Under the ‘directed source’ route, the OEMs direct the Tier-1 to source certain components only from a particular vendor. Also, SAF has a dedicated design, assembling and testing capability for ball joints.

The drive shafts (CV joints and propeller shaft parts) account for 40% of SAF’s product portfolio while brake parts account for 30% and the rest are ball joints. The forged aluminium yoke supplied by the company can be seen in a few vehicles including the Ford F 150. It may be noted that Ford has been very keen in light weighting its vehicles. And a testimony to this is the roll out of 2015 F-150 pickup on 11 November. The vehicle is made with aluminium body and bed that saves up to 320 kg, marking a significant milestone. The lightweight material is expected to increase fuel economy, but is more costly to make and repair, a big gamble for Ford’s best-selling vehicle.

Core Focus

Being a forging company SAF could have gone further making complete parts of a system; however, it confined itself to its core speciality of metal forming, because becoming a dedicated source for an OEM will be binding, opines Seetharaman. Considering the global automotive industry’s requirements, only Korea, Thailand and India are well positioned in offering technology products at competitive prices. Therefore, SAF is gearing up to forge ahead in tapping the emerging potential, concludes Seetharaman.

Hummingbird Attracting Flowers

Platform feeders, where the birdseed is simply put

down with a large screen, work very well. I would like

to thank Landstrom’s because of their assistance in providing background information. These feeders are pretty

self-sufficient and only require a good intermittent

refill and cleaning.