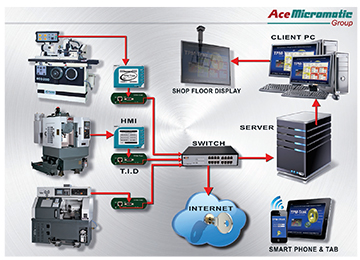

Micromatic Machine Tools (MMT) the customer face of a leading machine tool manufacturing company – Ace Micromatic Group, is focusing on new breed of smart machines that will help its customers to enhance overall productivity. Enthused by telemedicine concept the group company AceMicromatic Manufacturing Intelligence Technologies (AMIT) formerly known as Pioneer CT, has developed TPM Trak, an add-on hardware that helps users in monitoring Overall Equipment Efficiency (OEE) of the machine, the process using cycle level energy profiles, energy consumption among others.

Speaking to Auto Components India, the CEO of MMT, Ramesh TK said the key driver for developing the concept is the expectations from OEMs on reducing cost on a continuous basis. And for the Tier-1 companies and SME the opportunities to execute this exercise has been thinning down due to increasing cost for material, manpower and energy. However, automation is not the solution due to cost. Therefore, they are left with addressing only the nonproductive cost, which cannot be controlled without adequate data. “We thought that there can be some level of smartness be built into the machines,” and TPM Trak emerged.

Developed by AMIT, TPM Trak can be coupled with the new or existing machines marketed by MMT and with CNC machines from other brands. At the click of the mouse it can generate more than 60 different reports on many aspects including energy, interaction between support teams, work flow, process decay etc , and enable the users to take decision to not only manage the operations but also take corrective action early. Besides, the system helps the operator to alert different departments through SMS, thereby reducing the mean time to respond to one fifth of the normal time. Its compatibility with ERP and SAP make the monitoring process not only easier but also documenting the progress. As an extension it helps in offering remote diagnostics solutions to the customers, he said.

MMT has successfully deployed TPM Trak in hundreds of machines, most of whom are suppliers to vehicle manufacturers. “We have gone two stages beyond the prototype. For our first generation machines, there has been good response from customers.

Using this system, a leading auto component manufacturer based in Chennai could enhance operator efficiency from 65 percent to 89 percent and OEE from 65 percent to 80 percent. Besides, it also helped in reducing offset-connection (reason for machine stoppage) from 80 percent to nine percent and eliminate one shift. This is because the component manufacturer could see 15 percent improvement in the output per shift per machine, eventually reducing the manpower by one third. It was possible since the downtime analysis had been carried out on real-time basis and reduction in shop floor supervision because of operator being enabled to evaluate the process and improve on it. Interestingly, the return on investment is around 12 weeks, which is driving the customers to adopt this technology, Ramesh said.

MMT helps in setting new paradigms in productivity by interfacing the technological prowess of the group’s manufacturing units with customers. These include application engineering, commissioning and training, tech centres and monitoring of product performances.

Ace Micromatic Group hopes to touch Rs 3,000 crore as turnover by 2015. The group company reported Rs 1,000 crore in 2012-13 against Rs 1,200 crore in the previous year. The group is present in three segments – turning, milling and grinding. The market size (production minus exports plus imports) of turning machines is around 7,000 units with the group contributing to about 2,500 units. In the case of milling and machining centre size the market size is around 4,000 units with one fourth coming from the group. Annually about 300 CNC grinding machines are sold with the group selling about 130. Overall, the company holds about 33 percent market share in the segments it is operating in. ACI

Leave a Reply