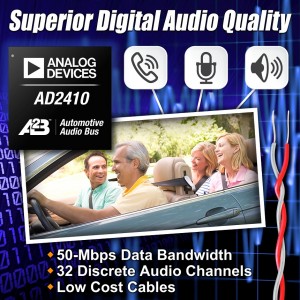

Analog Devices, Inc. a global leader in high-performance semiconductors for signal processing applications, introduced a digital audio bus technology capable of distributing audio and control data together with clock and power over a single, unshielded twisted-pair wire.

The AD2410 transceiver is the first in a family of devices that enables ADI’s new Automotive Audio Bus (A²B), which significantly reduces the weight of existing cable harnesses, resulting in improved vehicle fuel efficiency while delivering high fidelity audio. The transceiver also eliminates the need for expensive micro-controllers with large memories that are required in existing digital bus architectures.

The AD2410 transceiver is the first in a family of devices that enables ADI’s new Automotive Audio Bus (A²B), which significantly reduces the weight of existing cable harnesses, resulting in improved vehicle fuel efficiency while delivering high fidelity audio. The transceiver also eliminates the need for expensive micro-controllers with large memories that are required in existing digital bus architectures.

“As an early implementer of ADI’s A²B, Panasonic Automotive found the technology to significantly reduce cabling complexity and associated cost and weight of next-generation infotainment systems, key areas of focus for Panasonic’s OEM customers,” said Jonathan Lane, Group Manager, Audio & Acoustics, part of Panasonic Automotive Systems Company of America (PASA) Advanced Development Engineering. “We believe A²B to be well suited to address applications such as microphone arrays and Active Noise Cancellation, a leading area of expertise for Panasonic that we expect to be an integral component of next-generation infotainment systems.”

The AD2410 is a low-cost audio transceiver that provides 50 Mbps of data bandwidth and support for up to 32 discrete upstream and downstream audio channels. All standard audio sampling rates are supported as is daisy-chaining of multiple AD2410 slave devices to a single master. Unlike existing digital bus architectures, system delay is fully deterministic at all slave nodes, making it well suited for applications including active noise cancellation, in-car communications, and microphone beam forming. In addition to decreasing cabling complexity, the transceiver reduces audio system eBOM costs by providing a phantom power capability to all slave nodes, which eliminates the need for a local power source. The system meets all relevant automotive ESD, EMI, and EMC requirements. It operates over the extended automotive temperature range (-40C to +105C) and is fully AEC-Q100 qualified. It also includes extensive diagnostic capabilities enabling the identification of system-related failures. Besides, it is fully configurable using ADI’s SigmaStudio graphical development tool which minimises development time and ensures fast time to market.

Leave a Reply