Text : J Srikant

Precision and pinpoint accuracy have become the keywords in the auto component industry as Indian firms now directly compete with their European counterparts. While the bigger players have relied on technology to help them improve on this front, the small and medium auto component makers are learning the ropes of using hi-tech devices to get the desired accuracy to meet global standards. At the forefront of providing such hi-tech solutions to the Indian auto component majors, and now to the SME segment of auto components, is FARO Business Technologies India, a fully-owned arm of FARO Technologies, headquartered in Lake Mary, Florida, USA. FARO Technologies is one of the leading manufacturers of 3D imaging and portable measurement equipment.

FARO has been operating in India since 2004 and now boasts of having a close working relationship with the biggest OEMs in India. Maruti Suzuki, Tata, Toyota India and Eicher are some of the major customers of FARO. However, with small and medium auto components also getting technology savvy now, FARO believes that is where the next wave of customers will come from. “In general, in the last few years in India, I see better adoption of new technologies, particularly in the small and medium enterprises,” said Quah Beng Chieh, Head of Marketing, Asia Pacific, FARO. “The level of expertise and awareness has really grown in India. This bodes well for FARO as it is in the field of hi-tech devices. We definitely are focusing on this segment as the Tier 1 supplier who provides parts like transmission, crankshafts and engine components for them.”

FARO has been operating in India since 2004 and now boasts of having a close working relationship with the biggest OEMs in India. Maruti Suzuki, Tata, Toyota India and Eicher are some of the major customers of FARO. However, with small and medium auto components also getting technology savvy now, FARO believes that is where the next wave of customers will come from. “In general, in the last few years in India, I see better adoption of new technologies, particularly in the small and medium enterprises,” said Quah Beng Chieh, Head of Marketing, Asia Pacific, FARO. “The level of expertise and awareness has really grown in India. This bodes well for FARO as it is in the field of hi-tech devices. We definitely are focusing on this segment as the Tier 1 supplier who provides parts like transmission, crankshafts and engine components for them.”

In the past, this segment has been using fairly low-end devices. “Still many are using old, traditional processes. One reason could be the lack of knowledge and information about the new technologies which have entered the industry, with the initial cost playing a major role in dissuading companies from adopting the new technologies.” However, with increasing demand of precision components from OEMs, the components makers are left with no choice but to slowly and gradually make the forward move.

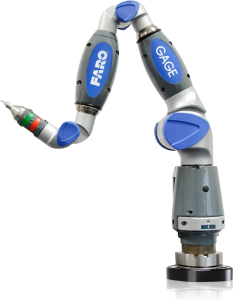

FARO in India has introduced all solutions that are available globally. Some of the key devices that FARO has in India are FARO Gage, a personal coordinate measuring machine which has its application in the auto industry in body-in-white and functional builds; FaroARM Fusion and FARo Edge ScanArm which are used in automotive industry for tool building and certification, alignment and part inspection.

The latest device that FARO introduced in India last year was FARO Laser Tracker Vantage. The laser-tracking based portable 3D measurement device gives high accuracy, multi-point scanning wherein 100 points can be scrutinized with just one scan, thereby reducing operating time considerably. The company said there also has been change in the requirement from the people who have been using this technology for some time. Companies want these hi-tech and complicated devices to be made easy to use. The main reason attributed to this is because companies don’t want to waste months or even days in training people to use these devices. They want the operators to hit the ground running.

Chieh said that the automotive industry is the biggest customer for Faro, traditionally and even today, followed by metal fabrication, shipbuilding, aerospace and the energy sector. However, he said there is no need to go for a dedicated solution for auto industry as the solution they offer is applicable to all industries. “We don’t have specific solutions for the auto industry, not because we don’t see it as a major industry but because we see a lot of similarities among different manufacturing industries,” he explained.

One of the reasons many companies do not opt for hi-end technology is the initial cost. To tackle this, a lot of the solution providers strip down their solutions and provide it to the companies at affordable costs. FARO differs from this strategy. “We don’t really believe in low-cost features. Because it essentially means taking away a lot of critical features or reduction of specs which I think in this auto component industry is not acceptable,” Cheih opined. Instead, FARO is educating its prospective customers to consider the total cost of ownership, which includes low cost of maintenance and minimum turnaround time, instead of the

One of the reasons many companies do not opt for hi-end technology is the initial cost. To tackle this, a lot of the solution providers strip down their solutions and provide it to the companies at affordable costs. FARO differs from this strategy. “We don’t really believe in low-cost features. Because it essentially means taking away a lot of critical features or reduction of specs which I think in this auto component industry is not acceptable,” Cheih opined. Instead, FARO is educating its prospective customers to consider the total cost of ownership, which includes low cost of maintenance and minimum turnaround time, instead of the

initial cost.

Operating with around 30 employees in India, FARO does not have a manufacturing or R&D facility here. Globally, the company does have R&D centres outside the main manufacturing plant that do some software development and a little bit of hardware as well. Most of it is due to acquisitions made over the years. The company said they are not averse to the idea of an R&D centre in India, if they are able to find the right partner for acquisition, joint venture or partnership. “It is always at the back of our mind,” a spokesman said.

Going forward, FARO’s plan

for India is to expand and increase the support & service network in the country. The company, which at present has two offices in Chennai and Delhi, is on the verge of setting up a third office in India. FARO has seen more than 20-25% growth from the Asia Pacific region which is its global average of growth. However, the recent slowdown in India in the auto sector did have an impact on FARO’s sales as well in the auto industry. “There was a slight dip from the auto industry but it was compensated for because we don’t focus on just one industry, but many,” asserted Chieh.

Leave a Reply