Ford Motor Company today announced details on new development techniques used to create its all-new Mustang and F-150, originating with the automaker’s suppliers. As Ford embarks on its most aggressive product launch year to date, with 23 launches globally – 16 in North America – the company is looking to its suppliers to help differentiate its products in the global marketplace, while continuing to meet customer expectations for safety, quality, sustainability and technology.

“As part of our One Ford plan, our suppliers are critical to creating profitable growth for all,” said Hau Thai-Tang, group vice president, Ford Global Purchasing. “With the industry’s highest product refresh rates, commitment to product excellence and innovation, and clear brand positioning, Ford is a preferred customer with the supply base.”

“As part of our One Ford plan, our suppliers are critical to creating profitable growth for all,” said Hau Thai-Tang, group vice president, Ford Global Purchasing. “With the industry’s highest product refresh rates, commitment to product excellence and innovation, and clear brand positioning, Ford is a preferred customer with the supply base.”At the Center for Automotive Research Management Briefing Seminar, Thai-Tang outlined several industry-first, Ford-supplier technologies that are being introduced on new 2015 products including:

- Quarter windows for 2015 Mustang 50 Years Limited Edition: Rather than a traditional plastic or metal louver that sits on top of the glass, Ford worked with Magna International to create quarter windows consisting of an industry-first louvered glass. The result is a modern homage to a classic design cue that is unique to the Mustang 50 Years Limited Edition

- Hydroformed A-pillar and roof rails, 2015 Mustang: To deliver top performance with the most efficient headroom package and weight, Ford worked with Schuler and Midway to engineer the heaviest-gauge steel hydroformed A-pillar and roof rails. Through the collaboration, torsional stiffness increases 28 percent for the new car while the body-in-white is lighter than the previous model

- Stronger, lighter high-strength steel frame, 2015 F-150: As part of Ford’s collaboration with Metalsa, the company used tailor-rolled blanks with variable material thickness, patented structures that reduce material usage without decreasing performance, increased high-strength steel from 22 percent to 77 percent and improved joining to take more than 60 pounds out of the frame while improving rigidity and enabling higher towing and hauling ratings

- Segment-first LED headlamps, 2015 F-150: Ford collaborated with OSRAM and Flex-n-Gate to design an innovative full-solid-state headlamp design that saves energy, is designed for longevity, and casts a much brighter and clearer light down the road than halogen or incandescent lamps. A jewel-like optical cube channels light energy from a single LED chip to provide optimal lighting and visibility

“Considering the impact suppliers have on our business, with 70 percent of the value of the vehicle being purchased from our supplier partners, our suppliers are critical to our ability to offer attractive solutions to our customers,” said Thai-Tang. “Ford’s Aligned Business Framework, which we introduced close to ten years ago, fosters an environment of transparency and will continue to guide our close relationships with our suppliers.”

Strong ties with suppliers

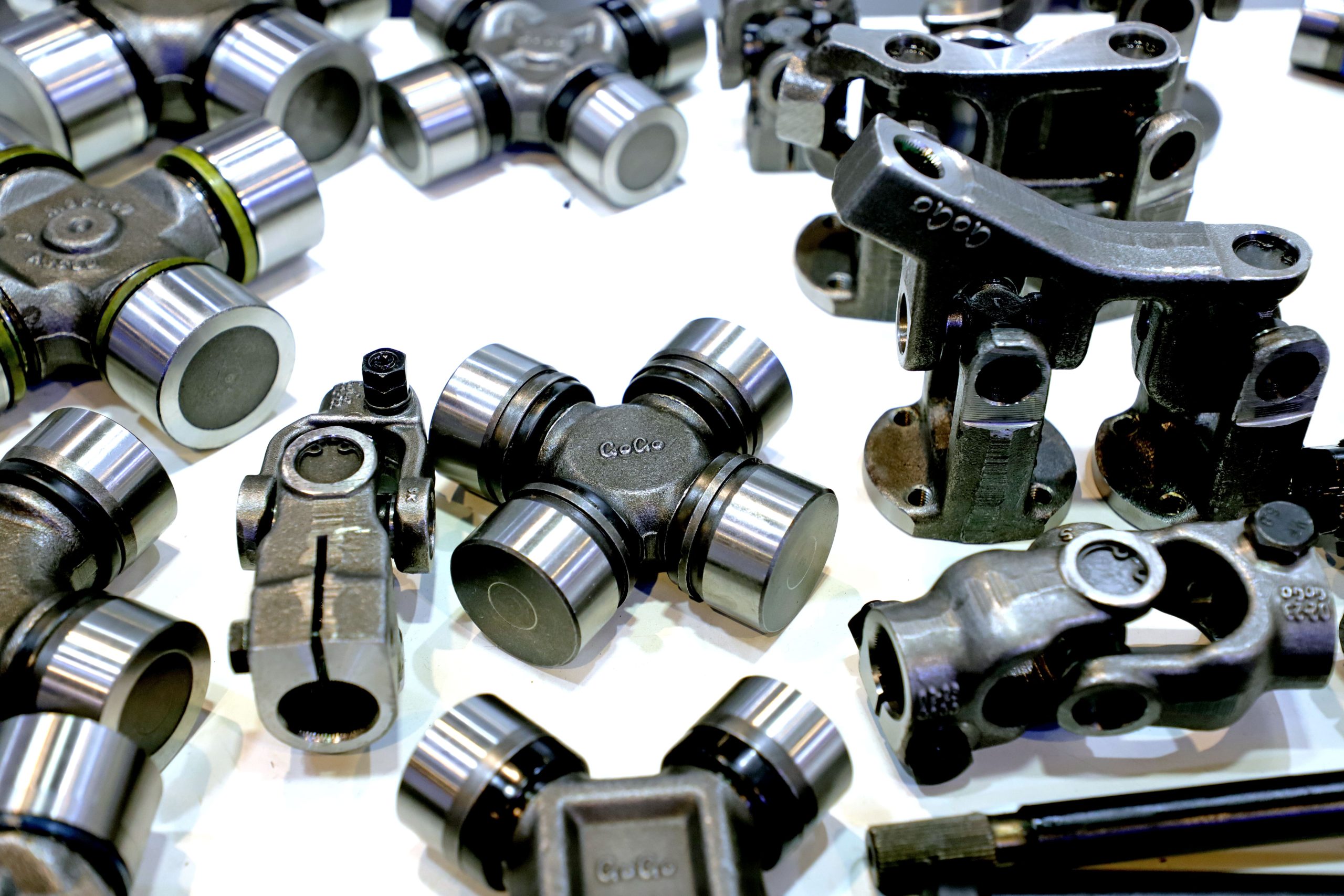

Ford has relationships with more than 1,100 production suppliers operating at more than 4,600 manufacturing sites that produce 130,000 parts for inclusion in vehicles the company sells. Because of the integral role its suppliers play in the company’s overall growth and sustainability, Ford works to foster a business environment that is both creative and transparent, leading to new innovations and acceleration in the development of new vehicles.

Ford has relationships with more than 1,100 production suppliers operating at more than 4,600 manufacturing sites that produce 130,000 parts for inclusion in vehicles the company sells. Because of the integral role its suppliers play in the company’s overall growth and sustainability, Ford works to foster a business environment that is both creative and transparent, leading to new innovations and acceleration in the development of new vehicles.

A core component of Ford’s strong supplier relationship is its Matched Pairs system, an internal alignment initiative between its product development and purchasing departments. Through the system, not only are the technical and commercial strategies aligned, but members from each department are paired so that decisions are made in tandem from the beginning. This approach increases collaboration from product design through procurement, and simplifies communication by reducing the points of contact for each commodity. The alignment of the two departments means they share a common cost objective, and improves interaction with suppliers by allowing them to engage directly at the right level.

The Matched Pairs system is part of Ford’s Aligned Business Framework. It enables supplier innovations to reach customers quicker by providing more robust tracking of new technologies, from idea to implementation. The framework encourages more communication between suppliers and senior Ford leaders, offers greater opportunities to increase scale, and engages suppliers earlier in the product design process. Ford has more than 100 Aligned Business Framework suppliers.

Another framework initiative helping to spur supplier innovation is the Executive Business Technology Review. This allows Ford’s senior leadership team from product development and purchasing to experience suppliers’ latest technologies through a show-and-tell, and for Ford to potentially be the first automaker to introduce these technologies to drivers around the world. Key technologies introduced through the review include Ford’s hands-free liftgate, active park assist and lane-keeping system, which debuted on various 2012 and 2013 Ford vehicles. Ford will continue to leverage its Aligned Business Framework to provide a systematic structure for suppliers to introduce new technologies to Ford customers.

“Many technologies on the road today were developed as a result of our supplier relationships,” said Thai-Tang. “We will continue to strive to be our suppliers’ customer of choice through our continued new product introductions and emphasis on technology excellence.”

Leave a Reply