India has a dubious distinction of being the country with a record of the highest road fatality rate in the world. According

to the Crime Records Bureau one human life is lost every minute due to road accidents in the country. In spite of roads becoming better, the rate of accidents has increased from 28.1% in 2006 to 32.6% in 2012. It is said that drivers are responsible for about 70% of the accidents that happen on roads.

As part of its initiative to reduce driver fatigue, which can eventually reduce

As part of its initiative to reduce driver fatigue, which can eventually reduce

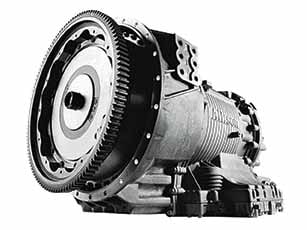

accidents, Wabco India has formally launched the Automated Manual Transmission technology – AMT OptiDrive,

for commercial vehicles. Though the technology has been prevalent in the Indian commercial market since 2012, applied in a few tarmac coaches and Ashok Leyland Boss, the global company has organised an event to demonstrate the system at its proving

ground in Mappedu village, about 40 km south of Chennai, for the media and a few customers.

Developed by Wabco of Europe the OptiDrive has been dominating the global market for AMT in medium and heavy commercial vehicles. The system combines the comfort and ease-of-use of an automatic transmission with the efficiency of a manual transmission. In addition to relieving the drivers’ stress in terms of constantly pressing the clutch pedal and shifting gears, it allows them to concentrate on traffic conditions. Besides this, the technology also helps increase fuel economy up to 5% in trucks and buses, the company claims.

Developed by Wabco of Europe the OptiDrive has been dominating the global market for AMT in medium and heavy commercial vehicles. The system combines the comfort and ease-of-use of an automatic transmission with the efficiency of a manual transmission. In addition to relieving the drivers’ stress in terms of constantly pressing the clutch pedal and shifting gears, it allows them to concentrate on traffic conditions. Besides this, the technology also helps increase fuel economy up to 5% in trucks and buses, the company claims.

Whole-time director of Wabco India, P Kaniappan said that in trials conducted in India, two fleets claimed average fuel savings up to 8% on buses fitted with AMT OptiDrive system. The system also addresses issues associated with the shortage of qualified drivers in India. It reduces driver stress and fatigue and improves driver effectiveness. As the technology is specially engineered as a

Whole-time director of Wabco India, P Kaniappan said that in trials conducted in India, two fleets claimed average fuel savings up to 8% on buses fitted with AMT OptiDrive system. The system also addresses issues associated with the shortage of qualified drivers in India. It reduces driver stress and fatigue and improves driver effectiveness. As the technology is specially engineered as a

modular system, it reduces by 50% the development time required for vehicle and transmission makers to apply this

in their respective platforms. These benefits enable even inexperienced drivers to operate with confidence and ease, he said.

Though the technology has been developed for 5 to 16-speed gearbox, in India it is tried for up to 9-speed transmissions. “Wabco expects to satisfy growing market demand and to expand its base of customers for AMT systems in India, which currently

includes original equipment manufacturers and fleets,” said Kaniappan. “We have been working on AMT programmes in India with major commercial vehicle manufacturers for their respective truck and bus platforms, and we believe our industry in India

could benefit greatly from adopting this technology more broadly.” Since 2012, the company has tested the system on over 500 buses.

The OptiDrive technology automatically engages the vehicle’s clutch and gear shift actuation considering the driver’s

operation, engine torque, vehicle load and road inclination, resulting in optimised gear shifting. In addition, the system

helps reduce wear on transmission components, clutch facing and service brakes, besides lowering maintenance

costs over the vehicle’s lifetime. Optimised gear-shifting also reduces emissions, resulting in an environmentally

cleaner footprint for fleets. Interestingly, the unit can be either retrofitted or directly fitted by OEMs on commercial

vehicles with manual transmission.

“OptiDrive shows Wabco’s technology leadership in automated manual transmissions as it continues to gain acceptance globally among makers of trucks, buses and transmissions, particularly in Asia and North America,” said Leon Liu, Wabco President, Asia.

“OptiDrive shows Wabco’s technology leadership in automated manual transmissions as it continues to gain acceptance globally among makers of trucks, buses and transmissions, particularly in Asia and North America,” said Leon Liu, Wabco President, Asia.

“We pioneered our industry’s first AMT system in 1986 in Europe where today more than 60% of trucks adopt AMT solutions, and are further differentiated as we still remain our industry’s only independent supplier of compressed air-powered AMT systems.” It may be noted that the global company has sold more than 2 million AMT systems worldwide since introduction.

Recently, Wabco India has partnered with a number of major commercial fleet operators in India, to newly develop

as well as retrofit AMT solutions, including trials on buses. For example, VRL Logistics, one of India’s leading transport companies, tested the OptiDrive system for six months on two buses and found that it saved on fuel. “Our bus drivers report more comfort

as there is no gear shifting and test findings indicate fuel savings from 5 to 8%,” said L Ramanand Bhat, Chief Technical Officer at VRL Logistics. “Our drivers prefer vehicles with AMT as it reduces their stress and fatigue, and based on our satisfactory experience, we have further adopted the AMT systems as original equipment fitment and retrofitment for a large number of

our trucks and buses.” Jorge Solis, Vice-President-Driveline Controls, Wabco Europe, said the payback period for investment made for retrofitment is estimated to be less than one year, though he did not disclose the cost of the system.

Technology

In AMT, the electromechanical or hydraulically operated actuators control the clutch and shift action based on the inputs received from the electronic control unit. The electronic control unit gets signals from sensors mounted at different locations. With scientifically optimised shift points the system helps reduce torque interruption to a minimum between shifts. The noticeable change in the vehicle fitted with AMT is the gearshift lever. Instead of the normal lever it has a short stem that operates like a toggle

switch. Besides, the gear knob has two soft-touch switches positioned on both sides – ‘Function’ and ‘Neutral.’ While

the function switch has to be triggered when the vehicle has to be moved from idle, the neutral switch helps the ‘go to

neutral’ position from any gear. All it demands from the driver is to activate the function key and press the accelerator

pedal. The vehicle moves forward and changes gears according to the user’s selection – ‘power’ or ‘economy’ mode. In the power mode the gear shifts at 2,000 rpm while it changes at 1,800 rpm in the economy mode, additionally saving fuel.

AMT also allows manual mode where the driver needs to push the gearshift lever forward like a toggle switch and

backwards for reducing the gears. However, the system will not allow the driver to reduce gears by skipping positions if

the vehicle speed is incorrect.

URL

… [Trackback]

[…] There you will find 58663 more Infos: autocomponentsindia.com/wabco-demonstrates-advanced-amt/ […]