Many resources are allocated for optimal thermal management in ICE and alternative green mobility solutions. Ashish Bhatia scouts the key advancements and aftermarket inclusions.

The most common way to keep systems cool is lubricants. Here, viscosity is known to be the most important property of a base oil. So much so that the health of the lubricant is monitored based on viscosity alone. Beyond viscosity, the role of additives within the lubricant is crucial. These are organic or inorganic compounds dissolved or suspended as solids in oil and normally account for between 0.1 to 30 per cent of the oil volume. They enhance existing base oil properties, suppress undesirable base oil properties, impart new properties to base oils and act as deactivators and tackiness agents. An interesting concept, cling has additives that attract contaminations like dirt, silica and water to in turn settle at the bottom or be filtered out depleting the additive package which is “sacrificial” in nature.

Coolants

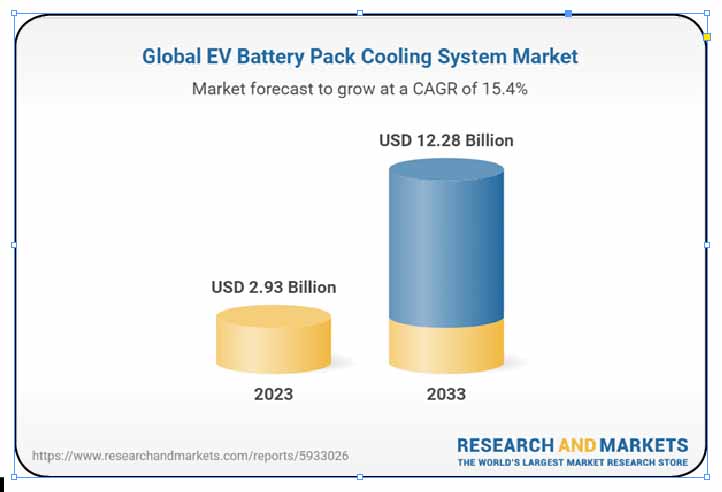

The engine cooling system market alone is projected to grow from USD 34.1 bn in 2023 to USD 49.7 bn by 2032. It translates to a Compound Annual Growth Rate (CAGR) of 4.8 per cent to set a context. An InsightAce Analytic Pvt. Ltd. study pegs the ‘Global EV Battery Pack Cooling System’ market at USD 2.85 Bn in 2023, and it is expected to reach USD 8.09 Bn by 2031, with a CAGR of 14.21 per cent during the forecast period of 2024-2031. Leading players like Dana, Boyd, Hanon, Kreisel, MAHLE, TotalEnergies, Valeo and XING are among prominent players. Complicated manufacturing processes and high up front costs are among the headwinds for the segment.

A simple search while scouting for coolants throws up jargon like ‘Antifreeze Green Concentrate’, ‘High-Performance Radiator Coolant’, ‘Premium Radiator Car Coolant’, ‘Heat Dissipation and Absorption Coolant’, ‘Green Engine Coolant’, ‘Cab Coolant’, and ‘Coolant Concentrate’ to name a few market-ready solutions. Gulf Oil, UE Autotech, Castrol, Bosch, Waxpol, Motul, Wuerth, Amsol, Liqui Moly, TVS Sprinter, Mapol, Manor and Mobil are available to choose from. Barox concentrate and pre-mix (Coola Revo 33 per cent and 50 per cent), a German brand are in the mix too. The claimed nitrite, amine and phosphate-free cost-efficient coolant concentrate offer freezing, boiling and corrosion protection. The company has a range of different segment applications.

Radiator advancements

Advancements have been made in radiators. For instance, the system, critical to keeping the engines cool is being developed with the use of advanced materials and new designs. From using aluminium and copper, radiators have graduated to using lightweight alloys and composite materials. The gains include improved heat transfer properties among other benefits.

Through integrated cooling systems, thermal management has improved. The combination of multiple cooling components like a radiator, and condenser into a single unit the enhanced heat transfer is complemented by by lower weight and space-saving for higher performance. Rheinmetall heat pump is positioned as a plug-and-play solution is compact and comes completely preassembled and filled. Boasting intelligent thermal management, it is claimed to increase the range of vehicles and the life span of materials. It enables precision climate control in the passenger compartment and offers intelligent conditioning of batteries in electric vehicles and drive components. A space saver, it is designed for both 400- and 800-volt applications and delivers up to eight kiloWatt of nominal cooling output and up to 11 kW of heating for battery-powered and hybrid systems.

The radiators designed especially for EVs have brought about concepts like liquid cooling for batteries and thermal management that assure optimal performance and extended battery life. It helps clear of unstable EV operations due to thermal runaway. From passive cooling systems, today’s active cooling systems hold promise. Electric fans, variable speed pumps, and thermoelectric cooling elements control both air flow and coolant flow as per requirements. Continental’s ultra-lightweight thermoplastic material optimises battery performance. Its High Performance Computers (HPCs) with expansion use additional modules and with the aid of a liquid cooling system make use of flexible cooling pads to keep the HPCs and components at safe operating temperature.

Apart, the use of sensors and IoT has radiators connected. Coolant temperatures, pressure and flow rates can all be monitored. This enables prognosis and predictive maintenance.

AI and one-stop shops

Tier 1 suppliers like ZF Group and Cummins Inc are leveraging AI for testing. Once the product is ready for testing, test benches are pressed into action. At ZF, virtual test benches are making use of AI to identify the relationship between thermal system behaviour and driving profiles. As per a Cummins study, 40 per cent of total engine repair costs are related to problems originating in the cooling system. Solutions like Fleetguard are claimed to offer an easy maintenance program. Claimed to protect from superior freeze and boilover, it addresses common cooling system issues: scale, corrosion and liner pitting. As a one-stop shop, it offers fully formulated heavy-duty antifreeze/coolants, Extenders and Supplemental Coolant Additives (SCAs), cooling system cleaners, and water filters – standard and extended service besides field and laboratory testing. Additionally, coil coolers designed to recover engine heat make use of ambient air as the cooling medium.

Presented at IAA Mobility, MAHLE’s new battery cooling plate developed a bionic structure. Modelled on nature for the cooling channels that cause the coolant to flow differently it is claimed to significantly improve the thermodynamic performance and structural-mechanical properties of the cooling plate. As a result, MAHLE claims to have increased cooling performance by 10 per cent and reduced pressure loss by 20 per cent. With reduced material usage in the plate by up to 15 per cent, it attained a 15 per cent CO2 saving. Marelli has been awarded a significant contract from a major global carmaker to supply the Battery Thermal Plate (BTP) for future Battery Electric Vehicles (BEVs).

The technotrans system is claimed to ensure the operational safety of the vehicles by cooling the battery and is particularly energy-efficient. Speed-controlled components sustainably reduce the CO2 footprint. The company bagged a major order from a well-known European e-bus manufacturer for the series production of BTMS valued in the high single-digit million euro range. It will be used in several new e-bus series. It supplies a total of three production sites in France and the Czech Republic. Norma, from mid-2024, is expected to deliver cooling water systems for the power electronics system for a customer’s new BEV platform. It comprises four models which are planned to hit the market successively from summer 2024-26. The Group will manufacture the cooling water lines at its plant in Pune, Maharashtra, and deliver directly to the customer’s plant also based in Maharashtra. ACI

Leave a Reply