The Bollhoff Group continues to pursue scale in fastening solutions. Prateek Pardeshi looks at the continual optimisation reciprocated through its exhibits.

The Bollhoff Group through its Indian subsidiary Bollhoff Fastenings Pvt. Ltd. continued to pursue a three-year strategy it first revealed in 2020. The strategy to invest in sustainable mobility holds good even today as the company aligns with ‘The New Global’ strategy or Vision 2024 formulated in 2021. Going beyond, the company also hopes to attain carbon neutrality by 2030. The display of ICE and EV-based solutions for its customer base are a testimony. As per the company’s global sustainability report, Wilhelm A. Böllhoff, a Member of the Board of Management, states, “A key element of our corporate strategy for 2024 is the continuous improvement of our resilience, adaptability, and sustainability.” This is expected to help the company double or triple the volume of sales of its fastening solutions.

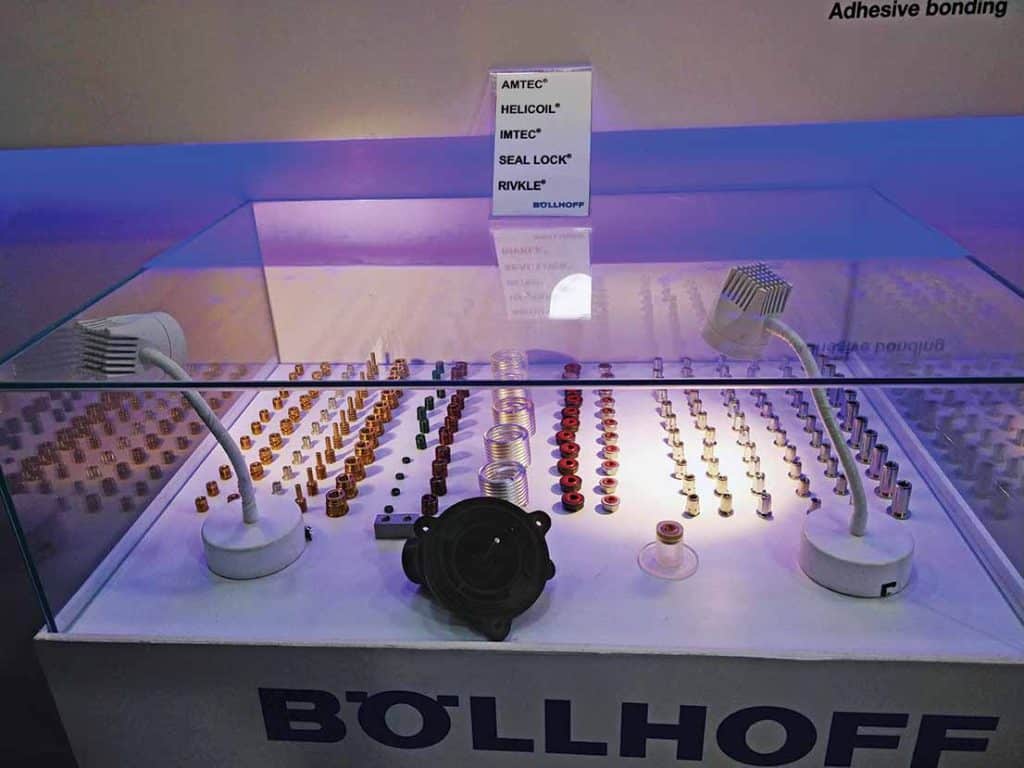

SNAPLOC ® – Decoupling fasteners, fasteners and fastening systems for decoupling of vibration and noise

Bollhoff Fastenings showcased joining solutions and assembly technologies. It showcased a wide range of fasteners, sub-assembly machines, quick releases, and thread inserts. The company drew attention with its thread technology, blind rivet technology, injection moulding technology, and mechanical joining technology. The portfolio encompasses a wide range of model products to meet assorted customer requirements. The RIVSET® Portable C on display is primarily used to join two or more sheets having an upper limit of five, having a total thickness of not more than six millimetres. The sheets are joined through the click of a button. It is a heat-retardant architecture. These machines are used for industrial purposes, primarily in automotive besides applications in the medical field. This machine is claimed to score over the fixed iteration given that its battery-powered and replaces self-pierce rivet heads directly at the installation site. The machine resonates the OE interest in it, with representation from companies like JLR and JBM Auto at different ends of the automotive spectrum. Persistent trends such as electromobility or lightweight construction necessitate appropriate joining technology solutions that the company has come to offer.

Addressable market

Looking at the growing penetration of EVs and OE customers introducing a range of products, the company has found an addressable market. It is witnessing a pull for components like high-speed joining, riveting technology, sealing technology for battery packs among other EV components. In India, Bollhoff is following the Japanese term Dojo for a focussed approach based on the pillars of concentration and shared learning for its stakeholders. The idea behind these dojos is that only well-trained employees fully understand the processes and customer requirements and in turn, deliver optimal product quality. This approach is known to drive the quality standards at the company.

AMTEC®, Thread inserts, brass high-strength thread inserts for plastic components; HELICOIL – thread inserts, used for high-strength fastening in metals having low shear strength; IMTEC ® moulding inserts, thread inserts for in-mounting; SEAL LOCK®- sealing nuts, sealing against®- gaseous and liquid media under high pressure, and RIVKLE®- Blind rivet nuts and studs, fastening of high-strength nut or stud thread to thin-walled components on display at the Auto Expo.

Bollhoff Fastenings, in India, supplies the AMTEC® inserts for thread creation in plastic components to various automotive tier 1 suppliers. Persistent trends such as electromobility or lightweight construction necessitate appropriate joining technology solutions and the decision makers at the supplier are of the strong belief that the renewed focus is on sustainability at a faster pace.

Vision 2024

The company is working towards its vision plan 2024. Here resilience and the capacity to quickly and flexibly adapt to changing circumstances form the core of its strategy. The ‘New Global’ must be considered as per the company document. This line of thinking pro actively addresses rising transportation costs, increased protectionism, and the risk of trade wars. ACI

Also read, A New Spark

Leave a Reply