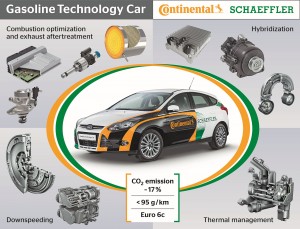

Continental and Schaeffler are taking advantage of the 35th International Vienna Motor Symposium to present the Gasoline Technology Car (GTC). The joint GTC project demonstrates how a networked integration of key mild hybrid technologies can cut fuel consumption as well as CO2 emissions by an additional 17% in the case of an already highly efficient car with downsized 3-cylinder gasoline engine – the Ford Focus 1.0 l EcoBoost. It also meets the limits set by the upcoming Euro 6c emissions standard (2017/2018).

“To achieve this level of hybridization, we have integrated and systematically networked key technologies from the Continental and Schaeffler portfolios into the GTC. The results we achieve with the vehicle point up the potential of this strategy in a car whose engine was nominated “International Engine of the Year 2012 and 2013” for its efficiency and performance,” says José Avila, Member of the Executive Board of Continental and President of the Powertrain Division.

To ensure driveability of the 3-cylinder, 1.0-litre engine, the GTC features an independent second drive unit, the 48 V Eco Drive System which includes an electric motor with integrated decoupling tensioner. The electric traction motor/generator is connected via a modified belt drive to the combustion engine. A DC/DC converter facilitates electrical energy flow between the 12 V voltage levels and the 48 V end with lithium-ion battery (dual-battery design). This hybridization supports the combustion engine electrically in the lower RPM range (e-boost function) to ensure attractive responsiveness without turbo lag.

In line with the strict design-to-cost approach, the GTC prototype is equipped with a conventional 6-gear manual transmission. Energy-saving functions such as coasting are also part of its drive strategy. The Schaeffler electronic clutch integrated into the vehicle makes this possible. It decouples the engine from the drive-train when the vehicle is coasting. Therefore the combustion engine does not decelerate the vehicle and thus more kinetic energy is available for recuperation. This energy, in turn, facilitates other efficiency-enhancing measures like the electrically heatable catalytic converter. It uses the recuperation energy from the previous drive cycle to attain a working temperature faster in cold starts.

The engine can be temporarily decoupled from the coolant cycle in order to attain the required temperature more quickly or to retain its temperature longer. The rapid heat-up reduces engine friction losses. As part of a forward-looking operating strategy, cooling can also be switched off in time for an anticipated recuperation phase, the downhill stretch.

The standard Continental engine control unit used in the GTC is designed to also relieve the combustion engine of the complex job of controlling the mild hybrid components, including the operating strategy. This engine control unit gets a head start on the upcoming EMS 3 strategy. Its open AUTOSAR-based system architecture flexibly supports various partitioning schemes and electronic topologies in conjunction with hybridization and electrification.

With manual transmission, top vehicle efficiency is achieved when the driver, the optimized individual components, and the vehicle functions are in sync. For this reason, the engine control unit makes downspeeding-oriented switch point recommendations. The additional electric driving torque allows the driver to use these switch points without any negative impact on drivability and achieve better fuel economy on the road.

Homepage

… [Trackback]

[…] Read More: autocomponentsindia.com/continental-and-schaeffler-present-innovative-mild-hybrid/ […]