BPW Trailer Systems is offering advanced trailer aggregates. Ashish Bhatia with Prateek Pardeshi looks into the compliance-driven strategy.

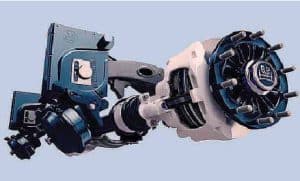

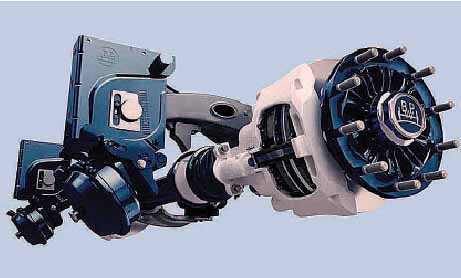

International trailer norms set the benchmark for the largely unorganised domestic trailer industry. With compliance codes like AIS-113 in place, the Ministry of Road, Transport and Highways (MoRTH) found it easy to model domestic norms on the lines of international markets. This led to the transport vehicle dimensions being standardised. And so, trailer aggregates have been forced to come of age too. Organised players like BPW Trailer Systems India Pvt. Ltd., specialists in the trailer running gear systems as a one-stop-shop, have spared no effort in meeting customer requirements like low Total Cost of Operations (TCO) and technologically advanced aggregates like axles, suspension systems and landing gear that includes lighting and cable system, brake cylinders, and air bags and axle lift systems to name a few.

International trailer norms set the benchmark for the largely unorganised domestic trailer industry. With compliance codes like AIS-113 in place, the Ministry of Road, Transport and Highways (MoRTH) found it easy to model domestic norms on the lines of international markets. This led to the transport vehicle dimensions being standardised. And so, trailer aggregates have been forced to come of age too. Organised players like BPW Trailer Systems India Pvt. Ltd., specialists in the trailer running gear systems as a one-stop-shop, have spared no effort in meeting customer requirements like low Total Cost of Operations (TCO) and technologically advanced aggregates like axles, suspension systems and landing gear that includes lighting and cable system, brake cylinders, and air bags and axle lift systems to name a few.

Commenting on the growing compliances forcing a technological advancement, Nagaraj Ubale, Director at BPW Trailer Systems India Pvt. Ltd, said, “On the trailer side, we can see the new pneumatic suspension technology, which justifies a 55-tonne capacity with a 4×2 tractor.” He quipped that on the tractor side, the customer expectations are higher today. “In order to deliver on the performance benchmarks like better fuel and operating economy, Ubale claimed that it took a careful understanding of the axle load norms on the company’s part.” “It changes the geometry of the vehicle completely. And because there is a lack of understanding, we are working with different agencies to cope with it .”

Driving the change

Back in 2018, axle load norms underwent a change to overnight increase the load-carrying capacity. The law came in after a gap of 35 years since the previous notification in 1983. The ripple effect was old aggregates were subjected to legitimate concerns of safety in the eye of the law. The axle up-gradation was inevitable and at the core of this mandate. It was to address lower axle weights resulting in higher logistics costs. The bearing on Gross Vehicular Weight (GVW) led to standardisation with combinations of axles in trailers being permissible subject to the capping on the GVW limits. In the case of modular hydraulic trailers, it necessitated the inclusion of appropriate axle row modules. With the notified changes, it was also decided that GVW must not exceed the safe axle weights and must not exceed the 49-tonne rigid vehicles and 55-tonne semi-articulated trailer specifications with the exception, with the exception of modular hydraulic trailers.

The MoRTH through GSR No. 414 (E) dated June 26, 2020, published a notification to amend Rule-93 relating to dimensions of motor vehicles under the Central Motor Vehicle Rules (CMVR) 1989. Expected to have a significant bearing on the logistics efficiency, the enhanced dimensions translated to extra carrying capacity and result in transporters requiring trailers with robust aggregates. For example, the pneumatic trailer under the notified changes was upgraded to be a part of the modular hydraulic trailer. It is expendable to 50 MTR without raising load to facilitate the transport of goods with exceptional length. Road trains with lengths at par with EU as 25.25 metres were proposed to be included on select routes. On the trailer aggregate companys’ part, the struggle is to overcome regulatory conflicts witnessed in inter-state travel. “The registration aspect of it is because a lot of changes have come into the axle norms that need to be sorted immediately otherwise the industry is doing fairly good,” opined Ubale.

BPW is catering to the global Original Equipment Manufacturers (OEMs) like Volvo Trucks in India who are placing these trucks on the road in segments like haulage and mining. It is also working closely with logistic firms like Express Logistics, to in turn help them meet their global requirements. Despite sales showing signs of a pickup hinting at growing customer acceptance, the company continues to iron out creases in order to fulfil the requirements of customers from the distiller industry.

BPW is catering to the global Original Equipment Manufacturers (OEMs) like Volvo Trucks in India who are placing these trucks on the road in segments like haulage and mining. It is also working closely with logistic firms like Express Logistics, to in turn help them meet their global requirements. Despite sales showing signs of a pickup hinting at growing customer acceptance, the company continues to iron out creases in order to fulfil the requirements of customers from the distiller industry.

Customer acceptance

Admitting to wide acceptance in the domestic market turning a challenge, BPW is leaving no stone unturned. It is extending its lead in the axle and suspension systems by expanding state-of-the-art assembly and manufacturing capabilities at its Pune facility. Claimed to have localised its mechanical suspension with tier suppliers, the company is meeting regulatory requirements with offerings in the 13-13.5-tonne confined capacity. A testimony to the company growing beyond the domestic pool of customers, on the export front, the company is exporting to quality conscious markets like Germany to name a few. Ubale credited this feat to its synchronisation with global quality systems and global supply chain management. This has helped the company offer localised products validated and tested to global standards.

Admitting to wide acceptance in the domestic market turning a challenge, BPW is leaving no stone unturned. It is extending its lead in the axle and suspension systems by expanding state-of-the-art assembly and manufacturing capabilities at its Pune facility. Claimed to have localised its mechanical suspension with tier suppliers, the company is meeting regulatory requirements with offerings in the 13-13.5-tonne confined capacity. A testimony to the company growing beyond the domestic pool of customers, on the export front, the company is exporting to quality conscious markets like Germany to name a few. Ubale credited this feat to its synchronisation with global quality systems and global supply chain management. This has helped the company offer localised products validated and tested to global standards.

Pushing limitations

Previously, for a higher Gross Combination Weight (GCW) realisations, trailers with Over Dimensional Cargo (ODC) were pulled by 6×2 or 6×4 axle combinations on a tractor. With the new regulations, 4×2 tractors explained Ubale, can now have the same GVW on the trailer side. Citing it as a significant change, Ubale admitted to taking time for settling down and working out the perfect market fits backed by compliance. “People are realising that there is a monetary benefit from these changes. Because, without any modifications, the vehicle is a 4×2 tractor with a six-wheeler trailer. So it is given the same GVW with the same three axles on the trailer, and it is a transition from an erstwhile preferred 10-wheeler. After sales offerings at BPW, the goal is to monitor all trailers with an AMC contract. When technological changes occur on the ground, periodic maintenance is critical, asserted Ubale. “With the BPW service portal, we can track all these trailers and their behaviours technically, like the brake system, the suspensions, the driver pattern which until now was the OEM’s responsibility,” he mentioned. With technologies like tyre inflation and monitoring system said to be under work, the company is pushing the boundaries in the after-sales segment as well. “I’m very happy to tell you that the BPW axle feature trailers are the first independently registered trailers. So this is a new requirement for the future, I think the tier2 and tier3 customers will realise the benefit in the near term, he concluded.

Leave a Reply