At ARAI research and execution continue. Prateek Pardeshi draws attention to the recent additions expected to benefit the automotive industry.

Developments and capacity expansion at the Automotive Research Association of India (ARAI) are a leading indicator of changes ensuing in the automotive industry with manufacturers working closely with the leading automotive R&D organisation. As ARAI prepares its 2030 roadmap, it continues to overcome the volatility induced by external disruptive forces with constant addition to its capabilities. For example, Electric Vehicles (EVs) have gained a lot of traction in the last two years. Batteries used in recent EV’s are generally out sourced and coupled with many different motors, and controllers. Often, due to overcharging or damaged battery, EV’s tend to malfunction and pose a safety hazard. To standardise this process, ARAI has worked to standardise battery safety regulations comprehensively. Averred Dr Reji Mathai, Director at ARAI, “The focus at ARAI is on meeting customer expectations; collaborative R&D to develop better solutions and technologies. ARAI defines the roadmap for 2030 and charters an implementation plan, until then execution and research at ARAI continues.”

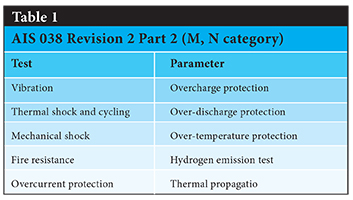

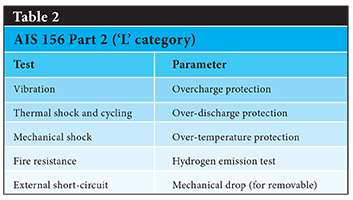

A motor vehicle with at least four wheels used for carrying passengers is categorised as ‘M’. A motor vehicle with at least four wheels used for carrying goods, which may also carry persons in addition to goods fall under category N. The regulation is known to remain standard for the M and N category with the Automotive Industry Standard (AIS) 038 Revision 2 (part 2) and aligned to the UN GTR (Global Technical Regulation) 20 Phase I and finalised UN R 100 (Rev 3). On the other end AIS 156 is aligned with ECE R-136 for L (L-category vehicles are a classification of road transport vehicles that range from powered two/three-wheelers including motorbikes, category vehicles.) The AIS 156 and AIS 038 Revision 2 standards that are known to focus on system level testing of the entire battery pack cover functional safety, risk reduction and mitigation analysis, and thermal safety with explicit mentions.

At the test laboratory, Original Equipment Manufacturers (OEMs) can look forward to tests in the realm of vibration, thermal shock and cycling, mechanical shock, fire resistance, external short circuit and over current protection (refer Table 1 and Table 2 below for details). The new facilities at the proposed ‘Battery Safety Test’ lab are expected to serve the industry’s needs of electrical abuse test and mechanical abuse test of electric and hybrid vehicles. The facility will also host thermal runaway, full-fledged BMS simulator, water immersion and battery pack crush facilities in days to come. ARAI is also known to augment existing battery testing capabilities by setting up the new laboratory in the view of increasing variety, sizes, capacities and volumes of xEV batteries coming in for testing, validation and development.

Electric Vehicles (EVs) are known to be silent to the extent of OEMs having to consider introducing an ambient sound. Synonymous to low NVH levels, the humming tyre continues to be a challenge though. To address this phenomenon known to occur especially with the tyre rolling at higher speeds, ARAI is offering its state-of-the-art test facility. It is aimed at providing tyre manufacturers with comprehensive certification services for the C1, C2, and C3 class of automotive tyres. In addition, the workshop is claimed to house all other vehicle evaluation and tyre handling support facilities. The nodal agency is currently conducting correlation trials in collaboration with the tyre industry. Standard Reference Test Tyres (SRTT) of relevant sizes will be conducted in a controlled environment as per reports.

In addition, ARAI is in the process of obtaining the NABL accreditation and offer support for all export homologation requirements in the future. For example, the noise test is performed using the vehicle coast down method with candidate tyres mounted on the test vehicle with a specified payload based on the tyre load index. To conduct the test, an instrumented vehicle carrying a payload enters a specific measurement area on an ISO: 10844 certified noise test track at a predetermined reference speed, and maximum noise is recorded using a microphone.

With the ‘Tyre Rolling Sound Emission Test’ facility, ARAI also facilitates testing of tyre adhesion over wet surfaces. The wet grip test is divided into two methods: vehicle method and trailer method. ARAI is in the process of acquiring a skid trailer system to cater to C1 and C2 class tyres in order to facilitate the trailer method and meet volumes. Furthermore, ARAI is in the process of acquiring a high-powered test vehicle for C3 tyres. The test lab offers a TUV certified test track, standard vehicles, a dedicated noise measurement system complete with required instrumentation besides a tyre changing facility.

Durability evaluation using six DOF

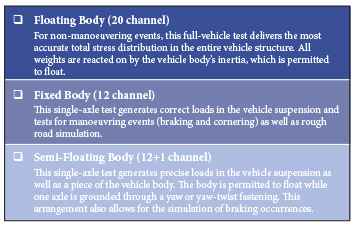

In order to evaluate the entire vehicle and reduce the Product Validation (PV) cycle, ARAI offers real-world simulation in a controlled environment. Using multi-Degree-Of-Freedom (DOF) testing complex components or structures are characterised. The full-car road simulator is deemed as the ultimate complete vehicle and component testing rig for both the front- and rear-axle fatigue testing, full-car stiffness testing, and suspension subsystem analysis. In its 12-channel version, the six DOF Road Simulator System (RSS) provides greater control over forces and involved motions. This includes translation in the vertical, to the side, along a longitudinal axis and control over torque of the brakes and the drive.

Three lateral struts, each with an own actuator, are known to operate together to control the lateral force as well as the steer and camber moments. The six DOF RSS is claimed to enable an accurate replication of the true multi-axial stress state of vehicle subsystems and components at any given point and time. These help simulate complex non-linear events required for meaningful durability road simulation using oproven linkage-coupled technology with an independent actuation. The most frequent mode of operation for this system is an inertially responded whole floating body, in which all of the inputs are reacted on by the vehicle’s inertia. This setup is deemed ideal for testing the entire vehicle’s durability, including the body, body-mounted components, and suspension.

Engine check

ARAI has a ‘Transient Test’ facility with an up to 600 kW at 1507-3381 rpm and a nominal torque of 3800 Nm at 1507 rpm with a maximum speed of 4500 rpm. It has a capacity to measure emissions and performance of both automotive and non-automotive engines (BSVI / EuroVI and BSIV & BSV CEV/Tractor Engines). This facility built with a vision to double up as a global R&D and testing facility is said to meet the requirements of upcoming emission criteria for non-road engines (BS-IV / BS-V CEV / Tractor) and automotive engines. This test facility is now undergoing commissioning and will soon be offered to the industry for automotive, CEV, genset, and other engine development work. It is LCV and HCV engine compliant to BSIV, BSVI emission standards. For Non-automotive (CEV, Tractor, Genset, etc.) engines compliant to Stage IIIA, BSIV, BSV emission standards. It is suitable for engines operating on fuel types like diesel, gasoline, CNG, bio-fuels (biodiesel), flex-engines (ethanol ED95 and methanol). The pre-and post-emission measurement system is compliant with UN ECE R49 Rev. 6, 40 CFR-part 1065, AIS 137 PART 4 & PART 7. Other USPs include calibration capabilities like FTIR, PM system, particle counter, fuel metre, water conditioning, temperature sensors, smoke metre and opacimeter among others.

Vehicle air-drag determination

A well-established and proven technology in the EU for simulation-based fuel consumption calculation and certification, at ARAI, the constant speed test aids in the calculation of air drag of heavy commercial vehicles by determining the forces at the wheels especially when the vehicle moves at a defined constant velocity. It is known to require precise instrumentation for acquiring the data within the defined test boundary conditions. Its the resultant measured output values from this test that aid in the determination of the air drag using an air drag tool. It makes use of the Wheel Force Transducer (WFT), differential GPS and mobile anemometer with phase-wise instrument calibration, vehicle warm-up phase, and a series of low speed and high speed tests. It helps ascertain an accurate air-drag given that the resultant values are independent of vehicle rolling resistance and other drivetrain losses. Specialised methods like CST aid in air-drag calculation for CVs. At ARAI, the exercise of air-drag determination also encompasses fuel efficiency and energy audit programs. ACI

A well-established and proven technology in the EU for simulation-based fuel consumption calculation and certification, at ARAI, the constant speed test aids in the calculation of air drag of heavy commercial vehicles by determining the forces at the wheels especially when the vehicle moves at a defined constant velocity. It is known to require precise instrumentation for acquiring the data within the defined test boundary conditions. Its the resultant measured output values from this test that aid in the determination of the air drag using an air drag tool. It makes use of the Wheel Force Transducer (WFT), differential GPS and mobile anemometer with phase-wise instrument calibration, vehicle warm-up phase, and a series of low speed and high speed tests. It helps ascertain an accurate air-drag given that the resultant values are independent of vehicle rolling resistance and other drivetrain losses. Specialised methods like CST aid in air-drag calculation for CVs. At ARAI, the exercise of air-drag determination also encompasses fuel efficiency and energy audit programs. ACI

Also read, The Rolling Resistance

Leave a Reply