Considered to be the flag bearer of EVs, Tesla, Inc has a strong supplier base in each country that it operates in. Ashish Bhatia looks at this ecosystem and the underlying opportunities for more suppliers in India.

It is well known that Tesla Inc. is setting its base in India after the country rolled out a red carpet for the EV flag bearer. The in-person plant visits at the Tesla headquarters, in Palo Alto, California, by the top political brass of the country led by Prime Minister Narendra Modi were followed by several state heads extending an invite to Co-founder and Chief Executive Officer Elon Musk for setting up the company’s India headquarters in their respective state. States like Gujarat, Maharashtra, Andhra Pradesh, Tamil Nadu and Karnataka were among the front runners. In phase one, while the company is expected to import its Model 3 series as part of a plug and play strategy, stakeholders of the industry are closely watching developments to gauge the overall approach.

It will be interesting to see if the company considers localisation eventually for sustenance and or building India as its global Research & Development (R&D), and manufacturing hub. When and if that happens, Indian component suppliers could win big! The company last put in place a strong leadership team with automotive honchos and continues to hire for both blue and white-collar positions across the country to get its execution right.

The supplier base

A look at Tesla’s global supplier base and country-specific strategies reveal how the company has put in place a robust ecosystem and built a strong supplier base to succeed in each of its markets. For starters, the company has always been discrete on who it partners with. It is seen as a means to retain its early mover’s advantage by protecting its intellectual properties to stay ahead of the competition. The intellectual property referred to includes electric powertrain and the expertise in developing self-driving technologies. The Tesla powertrain also consists of power electronics, motor, gearbox, and control software. The company credits its pool of powertrain variants to years of R&D behind the scenes as it basks in the glory of word of mouth. However, the company just can’t seem to do away with the attention it garners. Why should it! On the flipside, teardown exercises by competition threaten to encroach on its monopoly. Maintaining secrecy around its supplier base was and will never be an easy task.

Besides the battery pack, electric motor and charger that the company is known to manufacture itself, its core vehicle technology competencies also include battery and powertrain engineering and manufacturing. The company takes pride in its ability to design vehicles claimed to utilise the unique advantages associated with an electric powertrain. On the front user interface, the company designs in a manner to incorporate the latest advances in consumer technologies, such as mobile computing. Indian technology and gaming companies in the space could leverage the opportunities if Tesla were to look at both established and new entrants.

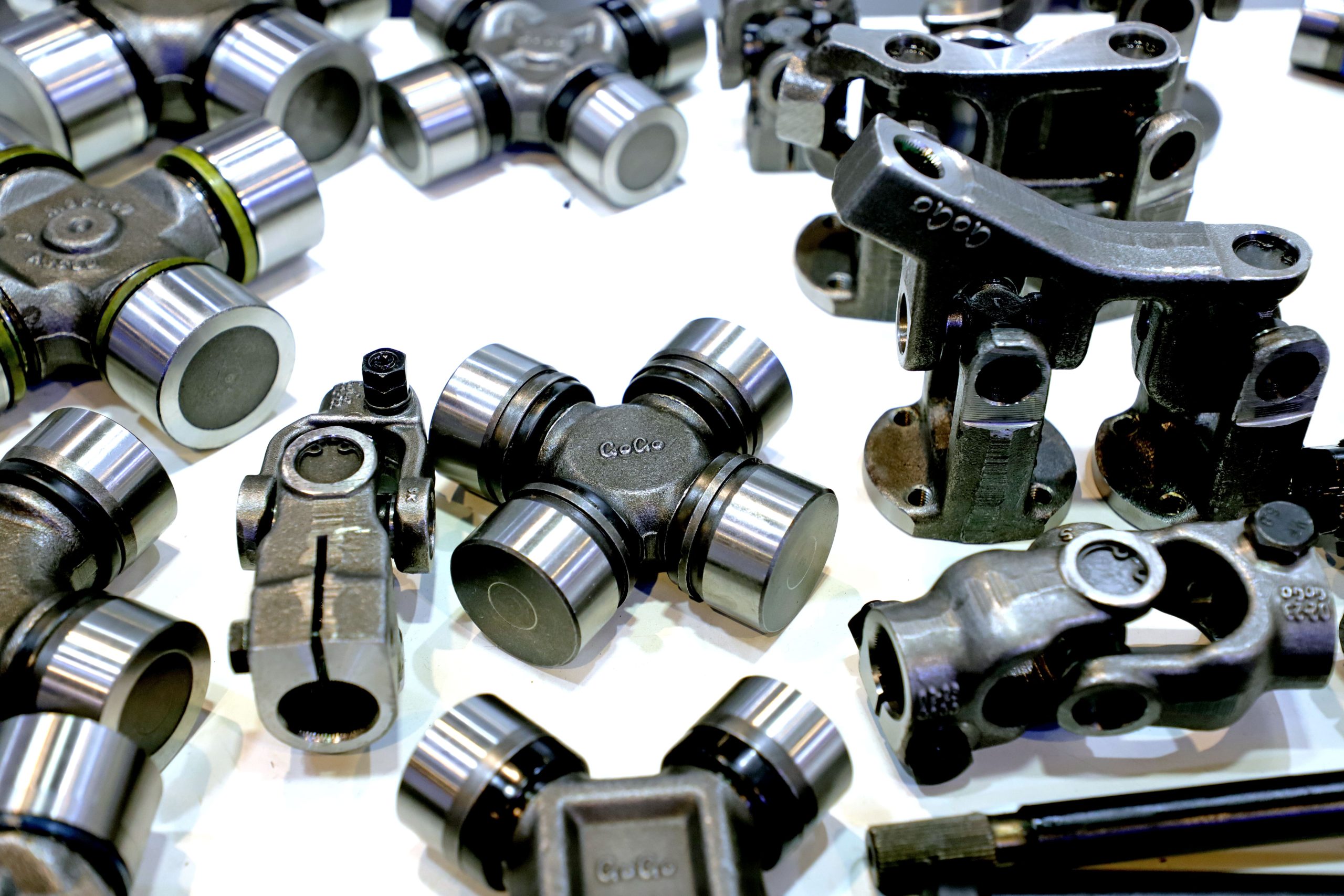

Tesla currently depends on component suppliers from across the United States, Europe and Asia including India to meet its other needs. Its supplier list includes AGC Automotive for windshields, Brembo for brakes, Fisher Dynamics for power seats, Inteva Products for the instrument panel, and Modine Manufacturing Co for the battery chiller. Sika supplies the acoustic dampers with Stabilus providing the liftgate gas spring. ZF Lenksysteme supplies the power steering mechanism. Continental provides the air conditioning lines while Magnetic Marelli provides the headlamp LEDs. NSK provides the wheel bearings and Wabco provides the twin compressor. GoldSeal-Saargummi India is known to provide body seals to the company.

And this is not even the tip of the iceberg. The list goes on to include other suppliers like ADAC, ABC Group, Angell-Demmel, Argent, Gentex, Harada, Hitachi Cable America, Hope Global, MacLean-Fogg, Magna International, Methode Electronics, Multimatic, Panasonic, Plastomer, PSM International, Riviera, T1 Automotive, Zanini Auto Group, TXU Corp., Universal Logistics Holdings, Inc., Affinia Group Intermediate Holdings Inc., Lithium Exploration Group, Inc., U.S. Lithium Exploration Group, Inc., Niocorp Developments, Ltd., Rare Element Resources, Ltd., Burlington Northern Sante Fe Corp., Cooper Industries, Ltd., Clarcor, Inc., Dana Corporation, Delphi Corporation, Flowserve Corp., NextEra Energy, Inc., Harman International Industries Inc., Lightwave Logic, Inc., Molex Inc., Metaldyne Performance Group Inc., Nortek, Inc., Rohm And Haas Company and Searchlight Minerals Corp.

Cost optimisation

Earlier in September 2020, Asian suppliers of Tesla were in the news after Musk is known to have pushed for lowering the cost of batteries. Batteries are estimated to account for 50 per cent of the total cost of an EV like the Tesla Model 3, for instance. To put its point across, the company hinted back then at eventually looking at producing its own cells to gain greater control over ballooning costs. The move is known to have compelled suppliers LG Chem Ltd., Contemporary Amperex Technology Co. Ltd. (CATL) and Panasonic Corp counted among the top tier battery suppliers to reevaluate their strategies.

USA based electric vehicle and clean energy company CATL, for now, has signed on an extension deal with Tesla to supply batteries until 2025 as per a stock exchange filing. To be able to optimise the vehicle cost from USD 37,990 to USD 25,000 by 2023, the company will have to work out ways to bring down battery costs in line with Musk’s objective made public on the company’s ‘Battery Day’ event.

Until Tesla can ramp up its own production, however, the company will have to rely on its existing supplier pool. In India, Indian battery pack manufacturers like Gemopai, Benling India, Okinawa Autotech and Ampere Electric, Amara Raja Batteries, Epsilon Advanced Materials Pvt. Ltd., and Green Evol Pvt. Ltd. (Grevol) among others in the pool of companies in the battery technology domain stand to benefit as a result. Low-cost and quality solutions could help the latter in breaking into the Tesla supplier pool. Such new entrants into the Tesla supplier pool are required to carefully assess and meet the quality benchmarks set by the company.

Quality Assessment

A battery solutions supplier, for example, will have to achieve high energy density at decreasing costs while also maintaining safety, reliability and long life in the extremely challenging and dynamic automotive environment like Tesla is claimed to have mastered. High-density energy storage, cooling, safety, charge balancing, structural durability, and electronics management are some of the other areas that need to be focused on. Tesla is open to evaluating new battery cells and optimising battery pack system performance to gain better control over the costs of its current and future vehicles. Indian suppliers can step up their game and capitalise on the intent.

Suppliers in power electronics need to match up to Tesla’s ability to drive large amounts of electrical current in a small physical package with high efficiency and low cost. It must also enable a recharge on a wide variety of electricity sources including at the company’s ‘Superchargers’. Motor manufacturers must benchmark with Tesla’s design, making use of two electric motors to maximise traction and performance in an all-wheel-drive configuration. It is said to pave the way for digital and independent control over torque to the front and rear wheels. In effect, the claimed, near-instantaneous response of the motors, combined with low centres of gravity, provide drivers with controlled performance and increased traction control. The company is also working on the development of vehicle powertrain technology featuring three electric motors to improve overall performance. Suppliers into steel, aluminium, copper and rubber besides alternative materials for body and chassis also stand a chance to associate with the company as it looks at ways to benefit from the use of a variety of materials and production methods for optimising vehicle weight.

A testimony to existing suppliers coming good on all counts is the manufacturer’s warranty on all new and used Tesla vehicles in global markets. A new Tesla vehicle comes with a four year or 50,000 miles ‘New Vehicle Limited Warranty’ to give a perspective on what the consumer gains. This is further subjected to separate limited warranties for a supplemental restraint system, battery and drive unit, and body rust perforation. In the case of the battery and drive unit on the new Model 3 and Model Y vehicles, the company offers an eight-year or 100,000-mile limited warranty for its ‘Standard’ or ‘Standard Range Plus battery’ and an eight-year or 120,000-mile limited warranty for its ‘Long Range’ or performance battery. The extended Service plans cover the repair or replacement of vehicle parts for up to an additional four years or up to an additional 50,000 miles after the expiration of the New Vehicle Limited Warranty. It will be interesting to see the fine print of this nitty-gritty in the Indian context and how more Indian suppliers capitalise on the prospects of a Tesla association. The company, for now, is content with setting up an assembly plant for CKD and SKD units in India. The new state EV policies and the government incentives also hint at support for Tesla to localise in the long run.

Also, read https://autocomponentsindia.com/will-covid-19-accelerate-the-electrification-revolution/

Leave a Reply