R.K Jain, Sr. Vice President – Commercial at Jindal Aluminium Limited in this article writes about meeting the EV demand through innovative production.

R.K Jain, Sr. Vice President – Commercial at Jindal Aluminium Limited in this article writes about meeting the EV demand through innovative production.

Policy incentives and technological advancements are going to guide the manufacturing and adoption of Electric Vehicles (EVs) in a big way, as India witnesses a sea-change in its attitude towards the segment. Electrified and efficient are words often used to describe the future of the automotive sector, which is also set to push the demand for aluminium exponentially. Innovation in products will continue to remain the focal point of the downstream aluminium sector.

A bright spot

EVs are a bright spot in the Indian automotive segment. They are a key element of the transition to cleaner energy. The Government of India data released earlier in Parliament has a promising story to tell. India saw 69,012 units of electric vehicles being sold in 2017-18. It scaled up to 1,43,358 units in 2018-19 and to 1,67,041 units in 2019-20. The growth in units includes sales of two-wheelers, three-wheelers and buses. Two-wheelers have led this growth. With the government setting its eyes on selling only electric cars in India after 2030, the sector is poised for the biggest renewable energy revolution the country has seen.

Making it drive

Aluminium is making the EV story successful. Used both in the manufacture of EVs and also in creating the necessary charging infrastructure. A higher performance metal, the push for EVs is adding importance to the role that this light and sturdy metal will play as it brightens prospects for the downstream aluminium segment as a whole. From addressing the challenge of helping vehicle manufacturers in the light-weighting of vehicles to improving the efficiency of conventional vehicles. In the case of EVs, it is a significant range extender. No matter the objective, aluminium extrusions are increasingly becoming a key part of the new-age solutions.

Customisation in production

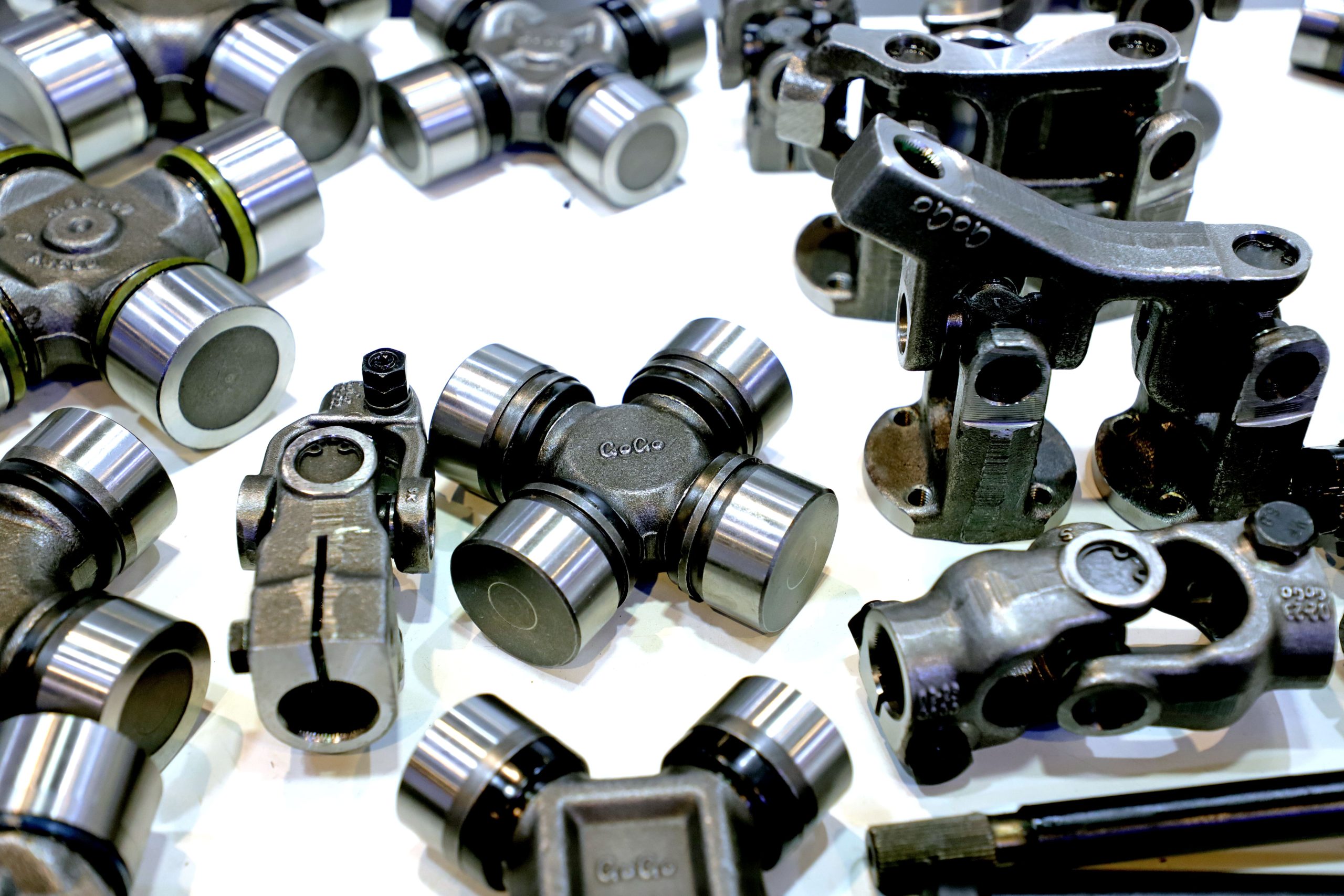

The shift to electric vehicles is no longer just an option; it is a must. India, China, many European countries, and the United States have all already decided in favour of emobility supported by research and development programs, charging infrastructure, and buyer incentives. This is an opportune moment for the downstream aluminium sector – which is an old partner of the automobile industry and finds its use in the making of the vehicle body, doors, trunks, hoods, bumpers, crash boxes, brakes, cables, wheels, etc. – to increase its overall usage. However, bringing about innovation in production is the need of the hour for the Indian downstream aluminium manufacturers if we want to meet the EV demand. Innovation in production is also crucial to raise the average quantity of aluminium used per vehicle from India’s average of 29 kg up to the global average of 160 kg or 250 kg as is projected for use in EVs in the times to come.

Economies of scale

Automobiles, whose bodies are made of aluminium are costlier than their other metal counterparts. This poses as one of the major obstacles to Aluminium’s market appeal in India. This will be addressed once the demand for EVs picks up and costs are lowered. As consumers get environmentally conscious and the government introduces policies that require vehicles to bring out more fuel-efficient variants going forward, expect the downstream aluminium sector to play an important role in the areas of fuel-saving, cutting carbon emission, costs, including repairs.

Time to innovate

Innovation is needed and is already being witnessed at various levels. For instance, in meeting the EV demand, the automobile industry is looking at major changes in vehicle manufacture with a focus on improved combustion, calibration, injection, and cylinder pressure. Downstream aluminium suppliers are meeting the needs through extrusions and rolling by using next-generation technology and innovation. The new applications of downstream aluminium include lightweight battery casings and heat exchangers, besides overall structural integration. Offering a higher strength-to-weight ratio compared to other metals, the ability to absorb a larger amount of crash energy, and to ensure that vehicular performance enhancements do not come at the cost of safety is what the downstream aluminium offers to the automobile industry, especially in meeting the EV demand.

All this, and the ease with which aluminium fits into creating simple and intricate shapes giving an elegant finish to the vehicle, make it an automaker’s dream metal. Thus, not only will this innovation in material supplied lead to light-weighting, lower costs, and meeting the commitments of going green, it will, through EVs, now offer a higher per-unit usage of downstream aluminium products in automobiles. ACI

———————————————

Jindal Aluminium Limited (JAL) is India’s largest aluminium extrusion company with a legacy spanning over 50 years. The company’s core business is the manufacturing of aluminium extrusions and aluminium flat-rolled products. With INR 30 Billion (USD 435 mn) turnover and with a production of above 1.25 lakh tonne in FY 2018-19, JAL is the leader in aluminium extrusions and is one of the leading companies in aluminium flat-rolled products in India..

———————————————

The opinions expressed within the content are solely the author’s and do not necessarily reflect the opinions of ACI Magazine.

Also read: https://autocomponentsindia.com/collaborative-innovation/

Leave a Reply