The plant will be commissioned in 2015 when the parent company celebrates its centenary

The plant will be commissioned in 2015 when the parent company celebrates its centenary

Rudi vo Meister, president – Asia- Pacific, ZF, behind the wheels of Tata Nano

ZF India Private Limited, the wholly-owned subsidiary of ZF Friedrichshafen AG, is setting up a new facility at an investment of Rs 150 crore to house Car Powertrain, Commercial Vehicle Technology, ZF Services and Engineering. To be commissioned in 2015 when the group celebrates its centenary, the plant will become the 122nd facility for the global company.

India is the second-largest sales market in the Asia-Pacific region for ZF that reported Euro three billion in 2013 of the total sales of Euro 17.4 billion. The Indian arm has been in production since 1984, initially through stake in a joint venture. After 2007, the group expanded its products and footprint, including ZF Lenksysteme GmbH, a joint venture between ZF and Bosch. At present the group supplements its portfolio in India producing axles and transmission for off-road machinery, as well as transmission and steering technology for commercial vehicles.

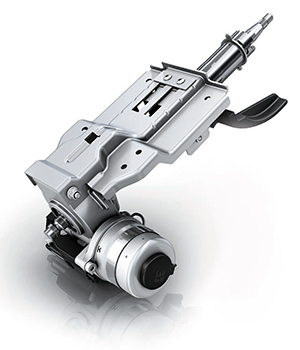

Columntype Electric-Power Steering

Columntype Electric-Power Steering

Speaking to Auto Components India, Rudi vo Meister, president – Asia Pacific, ZF said the new facility would initially employ about 350 people where passenger car powertrain, CV and services come together to strategically support customers in different segments.

The new facility will also be home to the headquarters of the engineering and administration of India operations, said Piyus Munot, managing director ZF India. A few weeks ago, the construction of the new building, on a 21-acre plot commenced in the Chakan industrial park, he said.

For 30 years ZF has been present in India and, “we see considerable potential in the Indian automotive industry in future. The country will contribute to the growth of the group which will be strongly driven by the Asia-Pacific region,” Meister said. He opined that by 2025 more than half of the revenue would come from outside of Europe with significant contribution from the Asia-Pacific belt. In 2013 the group generated about 40 percent of the global sales from outside Europe. After North America, Asia-Pacific is the largest international market for ZF Friedrichshafen AG, where it has 36 production locations and 61 authorised service partners.

Piyus Munot, managing director, ZF India

Piyus Munot, managing director, ZF India

To catalyse the transformation, the global company has evolved a strategy, ‘local-for-local’ to offer its customers products from local units wherever possible. In addition, it is also diverting its strengths to take up ‘design-to-market’ as a strategy to leverage the emerging potential in every region. Therefore, the upcoming facility is a step in this direction, which will develop products specifically for the requirements of the Indian market, he said. The process has already begun with engineers at development locations increasingly processing product or application development packages locally, factoring in the marketspecific requirements. Taking the cue from a recent development, Meister said the electric power steering system for passenger cars originally developed in Germany by ZF Lenksysteme GmbH was initially adapted in China for the Asian market. A variant for compact vehicles has recently been rolled out for Tata Nano with development work such as software, hardware, and electronics testing carried out locally, he pointed out. “Tata Nano is a gift to the world; it is the greatest takeaway for us,” at ZF, he said.

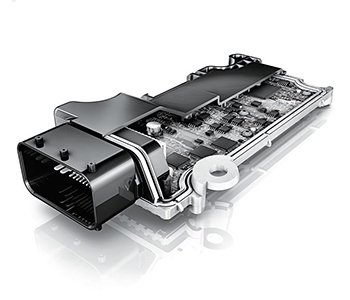

Engine Control Unit

Engine Control Unit

ZF Friedrichshafen AG will also look at sourcing components from this region, especially from India. Though he did not put a number to it, Meister said it would be substantial. Present in 121 locations across the globe, the group’s business from passenger cars and light commercial vehicles (under six tonne) accounted for about 70 percent of group sales last year. Since Asia Pacific is strong in these segments, the group is aggressively eyeing to be part of the growth trajectory. With its presence in almost all the automotive hubs in the world, the group has also created an efficient supplier base, Munot said. This helps the company in fully localising their products, he emphasised during a presentation as part of Ride & Drive India 2014 event organised by ZF India.

As part of the programme, the company showcased it capabilities in powertrain, chassis, commercial vehicle and industrial technologies. In driveline technology, ZF’s portfolio comprises manual and automatic transmissions including clutch systems and torque converters for every vehicle segment, and dual clutch transmissions and modules for passenger cars. Experts demonstrated the company’s eight-speed automatic transmission for passenger cars with a front-longitudinally mounted drive for the combination of driving dynamics, ride comfort, and efficiency. They also explained how the nine-speed automatic transmission transfers these benefits to passenger cars with a fronttransverse engine, which provides fuel savings of up to 16 percent compared with contemporary transmissions. In the case of commercial vehicles, the techies outlined the benefits of ZF-EcoLife, the six-speed automatic transmission for city buses and coaches. For the products the company makes, there were live demonstrations in vehicles including Nano, XUV 500, Mercedes, Audi, BMW, Jaguar, Land Rover, AMW, Ashok Leyland, Tata Prima, JCB and LeeBoy. ACI

Story : T Murrali