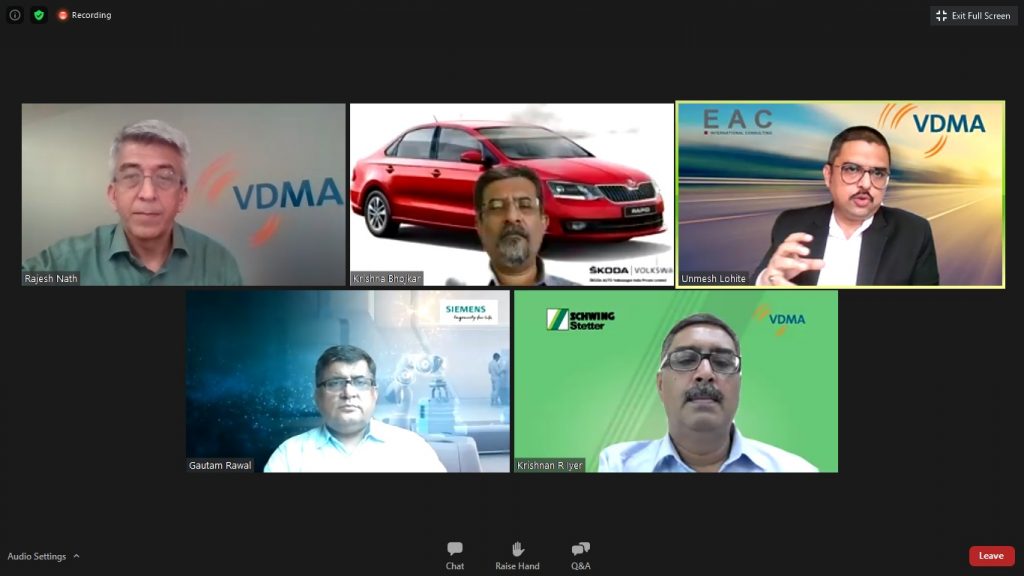

VDMA India and Euro Asia consulting had arranged a webinar on ‘Post COVID Opportunities of Robotics and Automation in Indian Manufacturing. This webinar was arranged for manufacturers in India who wanted to know faster ways to regain productivity and develop agility and resilience into their operations where robotics and automation emerge as a relevant solution for their operational and business goals. Panellists for the webinar were Krishna Bhojkar, Head Manufacturing Engineering Department at @volkswagenindia; Gautam Rawal, Country Business Unit Head, Factory Automation, @Siemens and Krishnan R Iyer, COO, Schwing Stetter India.

The webinar was moderated by Rajesh Nath, MD@vdmaindia and Unmesh Lohite, Principal, EAC Euro Asia Consulting where 350 attendees took part.

Unmesh Lohite, Principal, EAC Euro Asia Consulting started this webinar by discussing Covid-19 impact on Indian manufacturing. He explained about Robotics and Automation status in India and what are opportunities post covid

He further told about the role of R&A in recovery, status quo, cost factors, challenges, adoption parameters, decision factors, application potential, growing penetration and in end gave case studies of post covid R&A success stories.

Krishna Bhojkar, Head Manufacturing Engineering Department, SKODA – Volkswagen India

gave an overview of the Indian automotive industry. He explained the role, challenges and opportunities for Robotics and Automation in the Indian automotive industry.He said “When we look at the Indian industry. Typically, the OEs will be dependent on their sub-suppliers tier 123 or the MSME sections. This is one of the big challenges in front of the whole industry in India, that’s why it becomes important to know the way to survive””also need to look into its entire supply chain, and that is where questions are going to arise from. So it’s not only, independently looking, we need to continue the whole supply chain and ensure that we are able to survive,” he added.

gave an overview of the Indian automotive industry. He explained the role, challenges and opportunities for Robotics and Automation in the Indian automotive industry.He said “When we look at the Indian industry. Typically, the OEs will be dependent on their sub-suppliers tier 123 or the MSME sections. This is one of the big challenges in front of the whole industry in India, that’s why it becomes important to know the way to survive””also need to look into its entire supply chain, and that is where questions are going to arise from. So it’s not only, independently looking, we need to continue the whole supply chain and ensure that we are able to survive,” he added.

Gautam Rawal, Country Business Unit Head – Factory Automation, Siemens talked about the technological need of the industry in the digitisation era.Rawal said “To understand the core needs of the manufacturing is important which doesn’t change the pre covid or the post covid scenario, The topic presented are also pointing towards that speed, flexibility, quality efficiency and security””These are the four main areas which have got the relevance and would remain relevant. Their degree of relevance would change based on the situation we are in and in the post covid situation, there are some areas where we would have to do something urgently to take care” He added.

Krishnan R Iyer , COO,@SchwingIndia explained the impact of covid 19 on the industry where he divided his presentation into in into why what and how robotics and automation are need of an hour. Iyer said ” In western country, manpower is expensive, and is scarce. Their automation would be an automatic choice in a country like India where manpower is cheap. And then manpower is available, where there is a high rate of unemployment ” He added. “Where is the right kind of automation, what is the right kind of automation to be employed is very important because we also have to be socially responsible as companies, and that’s where the mindset of people need to be adapted accordingly” “Automation needs to be embraced so that there is no threat to the person that has a job stake, therefore, transforming the entire value quotient. By developing this resilience is going to drive efficiency and research as is found out that digital images mature companies”