A CII-Fluke joint live workshop pointed at the critical role of portable calibration tools in process optimisation.

Story by: Ashish Bhatia

Calibration aids better productivity be it helping in reduce the downtime or ensuring quality adherence and people and process safety. This formed the ethos of the Confederation of India Industry (CII) and Fluke Corporation’s jointly held live workshop, on process optimisation with portable calibration tools. Part of a six-series initiative, the live workshop offered testing, validation and calibration, test accuracy ratio required for a field asset, the decision on the final calibration or lab and workshop calibration, area and zone classification for intrinsically safe instruments, and tips for handling pressure calibration instruments as its key takeaways. It proved to be a runaway success with close to 200 delegates including instrumentation engineers having attended from across 21 states, spanning varied industries like manufacturing, heavy industries and automotive.

Process instruments

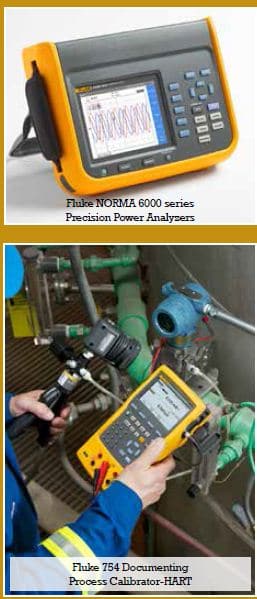

Drawing attention to process instruments for their productivity enhancement capabilities, K Joseph Selvakumar, Product Marketing Manager – Process Tools at Fluke Technologies ran the attendees through an array of process and test instruments. Making clear, the critical role of portable calibration tools in process optimisation, he drew attention to the capabilities of instruments in process plants like the models – Differential 750POO and Differential 750PO1. Taking the attendees through the fluke instrument’s specifications, he touched upon metrics spanning parameter range, burst rating, Hi and Lo side media, reference uncertainty and total uncertainty over a six month to one year period and metrics like subjected exposure to a 15-35 degree operating range. Spending time on the test uncertainty ratio, explained Selvakumar, it is the ratio of the tolerance or specification of the test measurement in relation to the uncertainty in measurements. Scenarios of the ratio pertaining to different in-tolerance probability, from 1:1, 2:1 to 4:1, correlating to the per cent of Unit Under TEST (UUT) tolerance band were touched upon in the session.

In the case of 4-20 mA loops, a known standard for signal transmission and electronic control in control systems since the 1950s, these are especially suited for automating a factory floor or taking field measurements. Popular for the fault detection in systems, explained Selvakumar, it enables process measurement of process variables like temperature, pressure, flow and others. It also helps to communicate 4 to 20 mA signal to the control system or control output and is digital. Fluke, he stated, offers reliable, rugged and accurate loop tools required for basic maintenance of analog process loops. The Fluke range of tools range from the lowest cost best-in-class performance tool – 705, highest precision portable mA/V – 715 to 787 and 789, claimed to be the world’s only 1000 volt IEC1010 Cat III DMMs with a 20 mA current source. The range also consists of 707 and 707Ex models for high-performance, one-handed operation. The Fluke 773 milliamp process clamp meter can measure mA signals without breaking the loop. Zero and span check, step function and ramp function are some of the other USPs.

In the case of 4-20 mA loops, a known standard for signal transmission and electronic control in control systems since the 1950s, these are especially suited for automating a factory floor or taking field measurements. Popular for the fault detection in systems, explained Selvakumar, it enables process measurement of process variables like temperature, pressure, flow and others. It also helps to communicate 4 to 20 mA signal to the control system or control output and is digital. Fluke, he stated, offers reliable, rugged and accurate loop tools required for basic maintenance of analog process loops. The Fluke range of tools range from the lowest cost best-in-class performance tool – 705, highest precision portable mA/V – 715 to 787 and 789, claimed to be the world’s only 1000 volt IEC1010 Cat III DMMs with a 20 mA current source. The range also consists of 707 and 707Ex models for high-performance, one-handed operation. The Fluke 773 milliamp process clamp meter can measure mA signals without breaking the loop. Zero and span check, step function and ramp function are some of the other USPs.

Temperature instruments troubleshooting tools range includes the Fluke 714B Thermocouple Calibrator, Fluke 712B RTD Calibrators and the Fluke 724 Temperature Calibrator. The tools are known to simulate process sensors for testing temperature instrumentation. In the pressure instruments troubleshooting tools range known to help instrumentation technicians calibrate and maintain pressure devices in process plants, Selvakumar familiarised the attendees with the range including model range without pump, built-in handpump, in-built motorised pump, dual pressure input, with the motorised pump, digital pressure gauge, automatic pressure generation and adjustment, pneumatic and hydraulic variants with the likes of Fluke 718 Pressure Calibrator, newly launched Fluke 730G Digital Pressure Calibrator, Fluke 730 RG Digital Pressure Calibrator and Fluke 719 Pressure Calibrator, Fluke 721 Pressure Calibrator, Fluke 729 Automatic Pressure Calibrator and Fluke 750P Series Pressure Modules. Add to it, Fluke also offers the Multivariable Transmitter and Pressure Transmitter troubleshooting tools in testimony to Fluke offering its customers the best of comfort, convenience and confidence while on the job. Multifunction calibrators enable operators to the source, measure and simulate varied process parameters and with the documenting versions additionally document the results.

HART transmitters popular in the automotive industry are offered with basic/universal commands compatibility. In the workshop, it was emphasised, that the test tools be certified to new Atmospheric Exolsibles (ATEX) regulations in view of making them intrinsically safe. Effective July 01, 2021, industries will be required to assess and categorise explosion risks at their plants and sites. Here categories 1G, 2G and 3G as per Selvakumar are the classification for gas explosion protection with 1G suitable for use in zones 0,1 and 2. 2G equipment for use in zone 1 and 2 and 3G equipment suitable for zone 2. Fluke, for instance, has the intrinsically safe true RMS digital multimeter that boasts of the ATEX, NEC-500, IEXEx safety certifications. Fluke ii900 Sonic Industrial manager offers acoustic imaging blended live sound map with a visual image. Using a seven inch 1280×800 LCD with capacitive touch screen, sensitivity detects 0.005 CFM leak at 100 PSI from up to 32.8 feet. With an operating frequency of 2kHz to 52kHz, it has a maximum operating distance of up to 164 feet (50 meters).

HART transmitters popular in the automotive industry are offered with basic/universal commands compatibility. In the workshop, it was emphasised, that the test tools be certified to new Atmospheric Exolsibles (ATEX) regulations in view of making them intrinsically safe. Effective July 01, 2021, industries will be required to assess and categorise explosion risks at their plants and sites. Here categories 1G, 2G and 3G as per Selvakumar are the classification for gas explosion protection with 1G suitable for use in zones 0,1 and 2. 2G equipment for use in zone 1 and 2 and 3G equipment suitable for zone 2. Fluke, for instance, has the intrinsically safe true RMS digital multimeter that boasts of the ATEX, NEC-500, IEXEx safety certifications. Fluke ii900 Sonic Industrial manager offers acoustic imaging blended live sound map with a visual image. Using a seven inch 1280×800 LCD with capacitive touch screen, sensitivity detects 0.005 CFM leak at 100 PSI from up to 32.8 feet. With an operating frequency of 2kHz to 52kHz, it has a maximum operating distance of up to 164 feet (50 meters).

Speaking on the evolution of instrumentation in the auto components industry, expressed Selvakumar, that the industry was an early adopter of instrumentation, case-in-point, Madras Institute of Technology, in Chennai. He drew attention to the turbocharger where based on the input pressure, the output boosts power and fuel supply. Instrumentation additionally also plays a critical role in automotive comfort, air-conditioning, lighting and power drives besides in power windows and in power steering. On the tipping point, he opined that there was a major change in the offing with EVs coming on to the mobility scene. Prabhakaran PV, Head – ICS Business & Business Development (SAARC Countries), Fluke India in his closing remarks thanked the delegates for wholeheartedly participating and making the live workshop success. ACI