Nissan engineers are using Model-Based Design with MATLAB® and Simulink® to reduce development and verification times for engine control software.

Story by: Hiroshi Miyagawa, Sales Manager, MathWorks

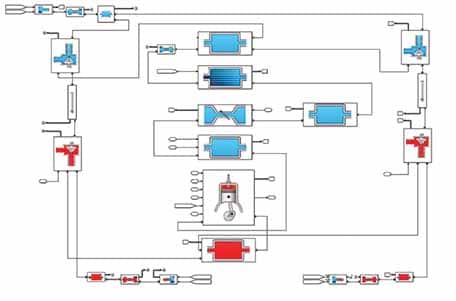

Nissan uses simulations with a plant model to evaluate all Software Components (SW-C) in the application layer written in Simulink. To account for a large number of engine variants in the company’s expanding product line, Nissan engineers have established a standardised workflow in which they use Simulink and Powertrain Blockset™ to develop engine model variants and perform Model-In-Loop (MIL) and Hardware-In-the-Loop (HIL) tests. “Using the Powertrain Blockset dynamic engine model as a starting point, we are able to create and refine plant model variants efficiently,” says Hiroshi Katoh, deputy general manager of the powertrain control engineering department at Nissan Motor Corporation. “We can use the same model for both MIL and HIL testing, greatly reducing the effort required and accelerating development,” he explains.

Nissan engine control software incorporates nearly 1500 SW-Cs. Nissan engineers use simulation to evaluate each of these SW-Cs for multiple engines with variations including displacement, number and arrangement of cylinders, and maximum torque. In the past, engineers tuned the parameters for engine model variants manually. Simulations using the models imposed heavy computational loads, leading to impractically long simulation times. Simpler models could be simulated faster but were less accurate. Because they used different toolsets for MIL and HIL testing, Nissan teams needed to create an entirely new plant model to conduct real-time HIL tests. To eliminate the duplicated effort and shorten testing schedules, Nissan wanted to use the same plant models for both MIL and HIL tests.

Nissan used Model-Based Design with Simulink and Powertrain Blockset to develop and test application software (ASW) for controlling the powertrain. The ASW contains some individual SW-Cs from suppliers. Nissan engineers use the Spark-Ignition (SI) engine dynamometer reference application from Powertrain Blockset as the basis for their engine plant model. They use the Resize Engine and Recalibrate Controller feature to automatically resize the engine model and adjust the calibration parameters based on settings such as the number of cylinders and engine displacement. The engineers make further modifications to the model as needed—for example, to model Exhaust Gas Recirculation (EGR) or turbocharger subsystems. To validate the engine model, the team executes built-in tests from the reference application and checks the simulated engine torque and other performance metrics. They then create a system model in Simulink by combining the validated engine model with a controller model, a transmission model, and a simple vehicle model.

Hiroshi Katoh, Deputy General Manager, Powertrain Control Engineering Department, Nissan Motor Corporation

Using an automated testing framework that they developed in MATLAB, the engineers conduct MIL tests to ensure the controller model meets specifications. This framework sets tests conditions, initiates simulations, and produces graphs for visualising results. In preparation for HIL testing, the team generates code from the engine model with Simulink Coder™ and deploys it to dSPACE® hardware. They run the same test cases used in MIL for the real-time HIL setup. Nissan has already used this workflow to evaluate engine control software for production vehicles, and they plan to use it to develop plant models for HIL and MIL testing of engine variants in upcoming new models.

Models for engine variants were created in hours, not days. “Previously, it took several days to modify an engine model for a new engine variant, but with Powertrain Blockset, we now do it in hours,” says Katoh. “As a result, we have accelerated the development of application software while ensuring quality,” he mentions. Code development costs got cut by two-thirds. “By modelling the control application software in Simulink and using the model as an executable specification, we have eliminated misunderstandings that can occur between OEMs and suppliers,” says Katoh. “Further, by generating code from our models, we have eliminated the bugs and human errors that come with hand-coding. These improvements enabled us to cut code development costs by roughly two-thirds and shorten development times,” he explains. HIL preparation time was significantly reduced. “With Simulink and Powertrain Blockset, we can use the same model for MIL and HIL tests. Having a common set of test cases, plant models, and tools for both environments has reduced the engineering hours required for HIL testing from one week to one day,” concludes Katoh. ACI