US-based technology firm Honeywell International is involved in engineering, development and manufacturing of turbochargers and related forced induction systems. In an email interaction with Auto Components India, Steven C. Gimre, Managing Director, Honeywell UOP India, and Dilip Malhotra, General Manager, Honeywell Transportation Systems India shared their views on connected plants and how turbochargers help in provide cleaner transportation.

Q: Kindly shed light on Honeywell’s ‘connected plant’ initiative.

Gimre: Honeywell Connected Plant (HCP) technology aims to promote digitisation in industries in support of the government’s Digital India effort. HCP’s transformative solutions enable manufacturers and process industries to leverage data and insights to improve the efficiency and profitability of their operations. HCP combines the company’s unmatched industrial expertise, software and cloud technologies to make its customers’ operations more reliable, profitable and secure than ever before.

Honeywell’s Connected Plant technologies enhance decision-making, increase security and productivity, and improve collaboration across the enterprise by providing the right information at the right time. These solutions cater to energy, manufacturing, infrastructure and other industries.

Q: What benefits can the automotive industry derive from the application of connected plant technology?

Gimre: India’s manufacturing sector is on a high growth trajectory. The Make in India programme aims to place India on the world map as a manufacturing hub and give global recognition to the Indian economy. The sector has the potential to touch US $1 trillion by 2025. If India is to achieve its goals of increasing manufacturing output to 25% of GDP and create up to 90 million domestic jobs by 2025, India will have to go further and drive innovation in the field of industrial automation. To accelerate efficiency and productivity, manufacturers will need to invest in energy efficient technologies and automation solutions and processes. The sector is therefore, reimagining the work place and the entire ecosystem – with computing inside.

The Industrial Internet of Things (IIoT) is the industrial revolution of the 21st century. In this industrial system, all processes such as product design, manufacturing, services and refurbishment are completely integrated and will exchange information in real time. This revolution will transform the manufacturing processes in synchronization with the speed of change in customer needs – which implies, making the production process flexible without taking excess time.

The most evident advantage IIoT brings to the table is increased productivity. In terms of efficiency, it provides supply chains with an increased level of future outlook of an enterprise. In terms of cyber security, it has been proven that isolated units are more vulnerable than connected ones. The full-fledged introduction of IIoT will bring about a greater measure of information security.

Q: How far has IIoT gone to the auto components manufacturing space. What does Honeywell do to provide efficiency and cost effectiveness in this domain?

Gimre: The emergence of IIoT represents a digital transformation of manufacturing that shifts the source of competitive advantage away from physical machinery and towards information. By delivering meaningful information where and when it is needed the most across the enterprise, IIoT opens up new possibilities for safety, productivity, organizational responsiveness and ultimately, profitability.

Honeywell offers a complete set of secure IIoT solutions in Smart and Secure Collaboration, Analytics, Data Management and Onsite Control and Smart and Connected Assets and Devices. The Honeywell Connected Plant also enables industrial transformation by offering production efficiency, reliability and enterprise optimisation

Our connected plant technology allows our customers globally to make far better decisions based on better insights. Our solutions enable a seamless integration from supply chains to production centres to the end-users. The access to expertise and knowledge that these connected solutions bring, provide a clearer picture for our customers in real time. This brings in increased collaboration, along with market demand.

Q: How does Honeywell gear up to leverage the prospective business opportunities from the stricter emission norms across vehicle segments?

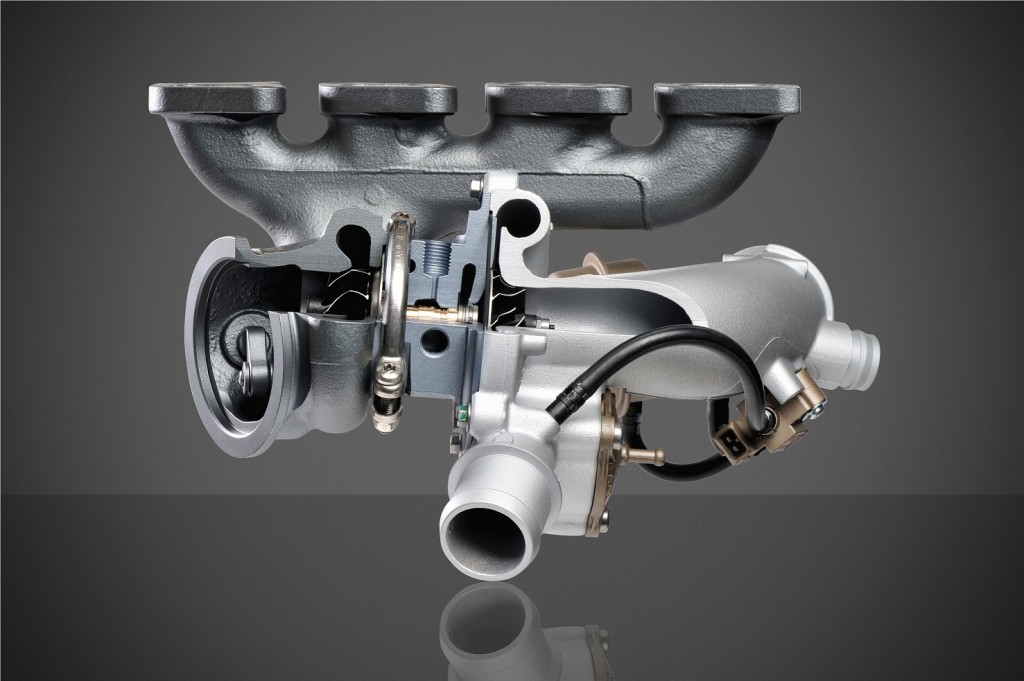

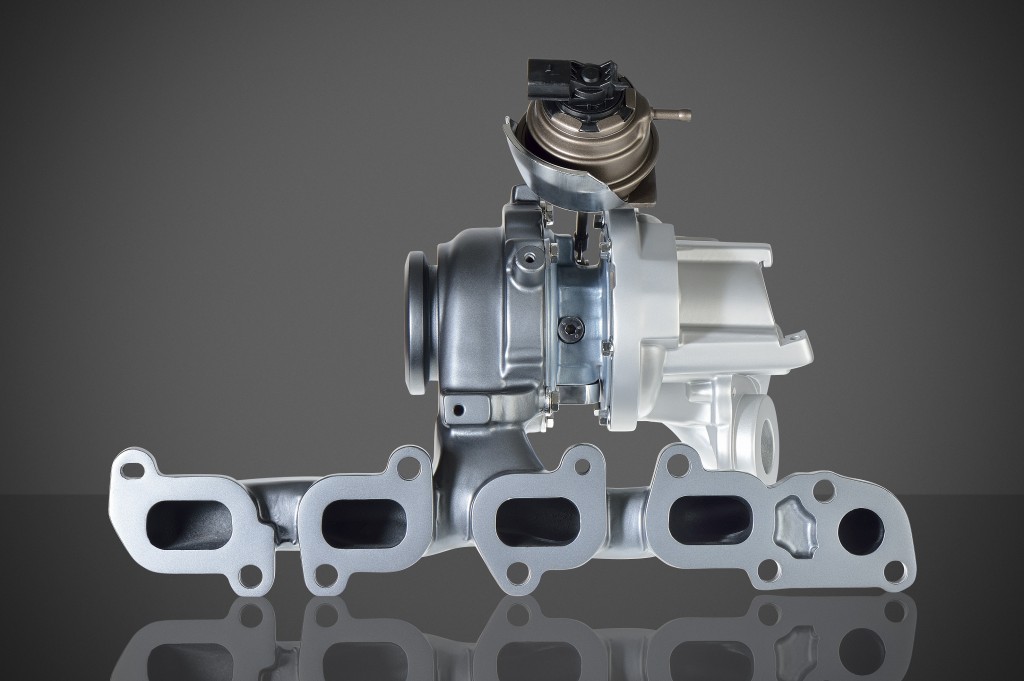

Malhotra: As emission regulations continue to tighten across automotive markets in India and other parts of the world, automakers are turning to turbochargers to help provide cleaner transportation. With the ability to reduce emissions and improve fuel economy by 20 to 40% in petrol and diesel engines, respectively, turbocharging technology is a smart choice for helping automakers meet tougher emission standards without sacrificing performance.

Our latest petrol and diesel turbocharger technology alongside electric boosting offerings, and the automotive software solutions are all helping automakers reduce emissions, increase fuel economy and improve performance. We at Honeywell are excited to help our customers with this next phase of development as powertrain optimisation has led to newer engine developments using alternative engine combustion cycles, electrification, multistage boosting and greater use of engine management solutions to provide greater fuel economy and emissions performance.

Q: What are your contributions to the preparations of the automotive manufacturers and oil companies to leapfrog from BS IV to BS VI?

Malhotra: Honeywell is committed to providing solutions to help automobile manufacturers’ transition to BS VI regulations with improvements in fuel efficiency, productivity and cost. We are one of the leading suppliers of turbocharger technologies globally and have helped car manufacturers in Europe meet the stringent Euro VI regulations (basis of BS VI standards). As turbocharging grows from being a technology broadly adopted in the west to a global technology, automakers in India are gaining valuable experience influencing current and future powertrain designs.

Honeywell continues to develop turbo innovations that enable automakers to push the limits of powertrain development across diverse portfolios, in the very demanding and sophisticated markets. Our global manufacturing footprint and supply base capabilities allow us to successfully respond to our Indian customers’ needs with high flexibility for global and local platforms.

Honeywell turbocharger applications are being used by most of the automakers in India to turbocharge the latest engines in their portfolio. Besides helping auto manufacturers meet BS VI emission standards, our turbochargers improve vehicle drivability and fuel efficiency.

For oil companies, refinery upgrades from BS IV to BS VI require significant investments in technology and processes. Honeywell is very well positioned, from a technology standpoint, to provide what the refiners need to meet these specifications. The size of the business opportunity here varies and depends on how far the refiner’s customers are from meeting these specifications. We have been helping the public and private sector refiners in India to achieve these goals and are seeing traction.

Honeywell is helping the state-run oil marketer, Hindustan Petroleum Corporation Limited (HPCL), to meet BS VI emission standards. HPCL will be using Honeywell technologies to upgrade its Vishakhapatnam refinery in Andhra Pradesh. The project includes licensing, basic engineering design, and other associated services for a Pene isomerisation unit, which helps make cleaner burning, high-octane petrol, and a Unicracking hydrocracking unit to produce cleaner burning diesel. Together, the 2 processes will enhance HPCL’s ability to supply petrol and diesel that meet the new BS VI clean fuels standard, and the growing demand for those fuels. They also improve gross refining margins by converting low-value feed stocks to high-value transportation fuels.

Q: What is Honeywell’s revenue from turbocharger business and what will it be in 2020? Which are the OEMs that you serve now?

Malhotra: The global turbo business is expected to reach almost $12 billion in industry sales in 2021. The projected increase in annual sales of vehicles with a turbo from 38 million today to 52 million in 2021 equates to a 35% increase, or 6% CAGR compared with a 2% CAGR for all global industry sales. We work with all major global and domestic customers for their domestic and export requirements.

Q: The penetration of turbochargers in petrol vehicles is lower than diesel vehicles. Also, the share of diesel cars is set to go down with stricter emission norms. When will turbochargers make the big entry to the petrol car segment?

Malhotra: Globally, diesel engines will retain an important share of light vehicle sales, due to their lower fuel consumption and CO2 emissions, even as petrol turbocharging capability and adoption grows in popularity. Consumers are adopting fast, and expect the highest levels of quality and reliability. Honeywell is capable of meeting the changing demands of the auto industry with its innovative technologies for both diesel and gasoline. In India, we can already see car manufacturers such as Tata Motors leading the adoption of gasoline-turbocharged engines. Honeywell is the proud partner with Tata’s first locally-developed gasoline turbocharged engine, Revotron, which is powering Zest and Bolt.

Q: Do you think the market for turbochargers in Europe has saturated? If so, are you shifting your focus towards Asia and Africa?

Malhotra: Europe will remain the global leader with an overall turbo penetration of 74% by 2021. The mix between petrol and diesel will shift slightly as petrol turbo penetration in light vehicle sales will grow 9 points to 52% in 2021. Additional technology benefits will be needed as many automakers still have a gap of 15 to 30 g/km before meeting the 2021 target of 95 g/km.

In China, emissions regulations are scheduled to become the toughest in the world. These new rules will favour the development of petrol turbocharged engines and wider adoption of electrification. China will be the highest growth market for turbocharged light vehicles with16 point increase in penetration of total sales. Other regions including Japan, Korea, India and South America will see on an average of 7% growth in turbocharging volume driven by the recovery of South America and South East Asian economies, and more stringent regulations including India’s BS VI and Brazil’s Inovar-Auto and future programmes.

While Europe will remain the largest market for turbochargers globally, high-growth regions such as China, India and South America will catch up fast, as the emission landscape across these regions evolves. Honeywell has wide presence and capability across all major global markets to respond quickly to the needs of our customers with locally relevant technologies.

Q: Industrial robotics is on a constant rise. What would be its impact on job, especially in the automotive manufacturing industry?

Gimre: Honeywell and the automation industry in general are enablers of efficiency. For every job that automation removes, IIoT creates an alternative one somewhere else. Honeywell in India is working to reduce carbon emissions, eliminate waste, improve plant productivity, create different skillsets and to build a new employment stream.

As per a recent report by Gartner, the risk to human jobs when roboworkers/ robotics enter the workforce in volume is obvious, but it is balanced by the need for talent capable of developing smart systems and autonomous processes. The future will belong to the companies that can create the most effective autonomous and smart software solutions. In the near future, jobs are more likely to be created than to be eliminated on a massive scale.

In this context, India has an edge over other countries with its younger population being tech-savvy. Combining the power of technology with the initiatives being taken in manufacturing will open new opportunities in the country. The manufacturing ecosystem is also being developed and evolved by players in this industry. Companies, governments, universities and colleges, consumers and service providers are part of this ecosystem. Owing to the increased awareness levels, everybody is working towards similar goals. This will bring the momentum in creating this ecosystem.